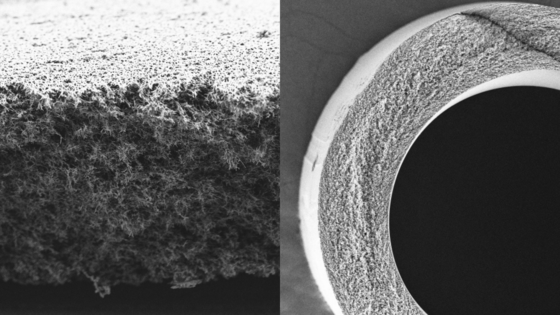

Oberflächen poröser Membranfilter

Membran-basierte Filtrationssysteme haben in den letzten Jahren eine stetig wachsende Bedeutung für zahlreiche Anwendungen, z.B. in der Hämodialyse, Wasseraufbereitung, Getränkeproduktion und anderen industriellen Filtrationsverfahren erlangt. Die Vielzahl unterschiedlicher Anwendungen erfordert eine spezifische Anpassung der Polymermembranen, um Fouling („Porenverstopfen“) zu reduzieren, um eine stabile und hohe Membranleistung zu erwirken, oder um katalytisch aktive Membranoberflächen zu generieren.

Entscheidend für die Membranperformance ist die Oberflächenwechselwirkung mit dem zu filtrierenden Medium. Hier bieten wir eine Kombination aus Kompetenzen und Technologien zur Funktionalisierung und Charakterisierung poröser Polymere mit strahlenchemischen Methoden sowie die technologische Ausstattung mit Anlagen vom Labor- bis in den Pilotmaßstab.

Wir fokussieren dabei auf Anwendungen im Bereich der Wasseraufbereitung, der Entfernung von Mikroschadstoffen und der Kreislaufwirtschaft.

Forschungsthemen

Team

Wissenschaftler/innen

Dr. Agnes Schulze

Dr. Daniel Breite

Dr. Martin Schmidt

Dr. Zahra NiavaraniPhDs

Tom Rüdiger

Tugce Sener Raman

Konrad Leopold

Julia Becker-Jahn

Tim SchreiberTechniker/innen

Isabell Thomas

Steffen Weiß

Marco Went

Mathias Kühnert

Amira Abdul Latif

Lutz DrößlerStudierende (Master)

Özgü Kirkayak

Highlights

Polymer Membranes for Active Degradation of Complex Fouling Mixtures

M. Schmidt, D. Breite, I. Thomas, M. Went, A. Prager, A. Schulze

J. Membr. Sci. 563 (2018) 481-491

https://doi.org/10.1016/j.memsci.2018.06.013Immobilization of different digestive enzymes consisting of proteases, amylases and lipases on polyvinylidene fluoride resulted in biocatalytic active polymer membranes with self-cleaning capability. Activation of enzymes and therefore “switching on” the membrane system was achieved by adjusting pH and temperature leading to an active degradation of fouled substances on its surface. Fouling and self-cleaning experiments with solutions of protein, lipid, carbohydrate, and a mixture were performed and resulted in high recovery of water permeance (99%, 72%, 77%, and 68%, respectively). Furthermore, real samples including river water (75% after first cycle), and household sewage (62%) were examined, as well as first investigations in longtime performance, and stability were performed. Comprehensive membrane characterization was conducted by investigation of the immobilized enzyme concentration, enzyme activity, fouling tests and water permeation monitoring, mercury porosimetry, X-ray photoelectron spectroscopy, scanning electron microscopy, and finally, zeta potential, as well as water contact angle measurements.

Radiation-Induced Graft Immobilization (RIGI): Covalent Binding of Non-Vinyl Compounds on Polymer Membranes

M. Schmidt, S. Zahn, F. Gehlhaar, A. Prager, J. Griebel, A. Kahnt, et al.

Polymers2021, 13(11), 1849

https://doi.org/10.3390/polym13111849Radiation-induced graft immobilization (RIGI) is a novel method for the covalent binding of substances on polymeric materials without the use of additional chemicals. In contrast to the well-known radiation-induced graft polymerization (RIGP), RIGI can use non-vinyl compounds such as small and large functional molecules, hydrophilic polymers, or even enzymes. In a one-step electron-beam-based process, immobilization can be performed in a clean, fast, and continuous operation mode, as required for industrial applications. This study proposes a reaction mechanism using polyvinylidene fluoride (PVDF) and two small model molecules, glycine and taurine, in aqueous solution. Covalent coupling of single molecules is achieved by radical recombination and alkene addition reactions, with water radiolysis playing a crucial role in the formation of reactive solute species. Hydroxyl radicals contribute mainly to the immobilization, while solvated electrons and hydrogen radicals play a minor role. Release of fluoride is mainly induced by direct ionization of the polymer and supported by water. Hydrophobic chains attached to cations appear to enhance the covalent attachment of solutes to the polymer surface. Computational work is complemented by experimental studies, including X-ray photoelectron spectroscopy (XPS) and fluoride high-performance ion chromatography (HPIC).

High Flux and Adsorption Based Non-functionalized Hexagonal Boron Nitride Lamellar Membrane for Ultrafast Water Purification

R. Das, P. Solís-Fernández, D. Breite, A. Prager, A. Lotnyk, A. Schulze, H. Ago

Chem. Eng. J. 420 (2021) 127721

https://doi.org/10.1016/j.cej.2020.127721Water pollution has prejudicial effects on human health and ecosystems. An advanced membrane technology, which uses less energy for pollutants removal from water, is strongly desired for improving cost efficiency. This study demonstrates a high-flux enabled non-functionalized hexagonal boron nitride (h-BN) lamellar membrane, which retains pollutants through adsorption mediated filtration system–a phenomenon that is not yet studied. The membrane is found to be pH responsive, and acidic solution increases anionic methyl orange (MO) and direct red-80 (DR-80) dyes retention up to ≥90%. It also improves permeance fluxes by ~15 and 61-folds for MO and DR-80, respectively, as compared with the previous studies. Next, the membrane qualifies to be a good adsorbent for pollutants removal. The maximum adsorption capacities of this h-BN membrane for bisphenol A, MO and DR-80 are 125.7, 120.8, and 328.2 mg g−1, respectively. Furthermore, the anti-fouling performance of the membrane has been studied. The membrane exhibits normal fouling tendency, but could be recovered to 80% after washing. The membrane is very stable, and no swelling is observed even in extremely high acidic and basic conditions. The membrane could be regenerated with ethanol treatment and retained dye removal efficiency (around 90%) after four consecutive cycles test.

Photocatalytic degradation of steroid hormone micropollutants by TiO2-coated polyethersulfone membranes in a continuous flow-through process

S. Lotfi, K. Fischer, A. Schulze, A. I. Schäfer

Nat. Nanotechnol. 17 (2022) 417-423

10.1038/s41565-022-01074-8Micropollutants in the aquatic environment pose a high risk to both environmental and human health. The photocatalytic degradation of steroid hormones in a flow-through photocatalytic membrane reactor under UV light (365 nm) at environmentally relevant concentrations (50 ng l–1 to 1 mg l–1) was examined using a polyethersulfone–titanium dioxide (PES–TiO2) membrane. The TiO2 nanoparticles (10–30 nm) were immobilized both on the surface and in the nanopores (220 nm) of the membrane. Water quality and operational parameters were evaluated to elucidate the limiting factors in the degradation of steroid hormones. Flow through the photocatalytic membrane increased contact between the micropollutants and ·OH in the pores. Notably, 80% of both oestradiol and oestrone was removed from a 200 ng l–1 feed (at 25 mW cm–2 and 300 l m–2 h–1). Progesterone and testosterone removal was lower at 44% and 33%, respectively. Increasing the oestradiol concentration to 1 mg l–1 resulted in 20% removal, whereas with a 100 ng l–1 solution, a maximum removal of 94% was achieved at 44 mW cm–2 and 60 l m–2 h–1. The effectiveness of the relatively well-known PES–TiO2 membrane for micropollutant removal has been demonstrated; this effectiveness is due to the nanoscale size of the membrane, which provides a high surface area and facilitates close contact of the radicals with the very small (0.8 nm) micropollutant at an extremely low, environmentally relevant concentration (100 ng l–1).

Synthesis of composite imprinted polymer membranes for the selective removal of 17β-estradiol from water

Z. Niavarani, D. Breite, A. Prager, I. Thomas, M. Kuehnert, B. Abel, R. Gläser, A. Schulze

Mater. Chem. Front. 7 (2023) 4460-4472

10.1039/D3QM00345KComposite microfiltration polyethersulfone membranes incorporating molecularly imprinted particles (MIPs) were developed for efficient and selective adsorption of 17β-estradiol from water. MIP particles were synthesized via precipitation polymerization, with 17β-estradiol as the template molecule. The composite membranes were prepared by embedding the MIPs into the membrane matrices using phase inversion process. Electron beam irradiation was used to covalently immobilize the MIP particles within the membrane scaffold. The synthesized membranes were characterized using scanning electron microscopy (SEM), X-ray photoelectron spectroscopy (XPS), water contact angle analysis, permeation tests and mercury porosimetry. The adsorption loading, selectivity, reusability, and adsorption isotherms were studied through batch and dynamic adsorption experiments. The results indicated significant adsorption loading of 17β-estradiol (12.9 ± 1 mg g−1) and selectivity factors as high as 6.2 and 12.5 for 17β-estradiol in the presence of model micropollutants (such as bisphenol A and citalopram), respectively. Moreover, the composite membranes were regenerated and reused without any significant loss in adsorption loading for 10 subsequent cycles. The maximum adsorption capacity of 17β-estradiol on the composite membrane, calculated by fitting experimental data with the Langmuir equation, was 21.9 mg g−1, which is more than a 200-fold increase in the adsorption loading compared to commercial nanofiltration. These composite microfiltration membranes exhibit a high adsorption loading accompanied by lower pressure requirements for filtration, high water permeation, and extended reusability, rendering them a viable and sustainable option for water purification processes.

Projekte

Biomasse 2.0 - Aleno: Anaerobic light-enhanced N-oxidation

Faulstufen von Kläranlagen, welche nach einem Aufstromprinzip arbeiten, zeichnen sich durch einen hohen Biomasse-Rückhalt, sowie eine schnelle Umsetzungsrate aus. Zu nennen sind hier die Reaktortypen UASB (Upstream Anaerobic Sludge Blanket) und EGSB (Expanded Granular Sludge Bed). Aktuell besteht jedoch das Problem, dass derartige Systeme nicht in der Lage sind, eine Entstickung (N-Elimnierung) vorzunehmen, so dass nach wie vor eine Kopplung an Belebungsschlammverfahren mit Nitrifikation und Denitrifikation einzuplanen ist. Eine Entstickung in UASB/EGSB Reaktoren ist nach aktuellem Stand der Technik nicht möglich, da der hierfür benötigte Sauerstoff eine schnelle Vergrößerung von mikrobiellem Granulat verursacht. Im geplanten ALENO-Projekt soll ein neuartiger Aufstromreaktor entwickelt werden, welcher eine anaerobe Entstickung mit hoher Reiningungseffizienz und gleichzeitiger Energiegewinnung kombiniert.

Projektträger: VDI/VDE

SolPol-6: Entwicklung maßgeschneiderter und ökoeffizienter Polyolefinwerkstoffe für solare und nachhaltige Energietechnologien

Der Übergang von fossilen Brennstoffen zu erneuerbaren Energiesystemen beinhaltet die Umstellung von Hochtemperatur- auf Niedrigtemperaturprozesse und den Übergang von komplexen Materialien zu ökoeffizienten Materialien wie Polymermaterialien, die in einem vollständig solaren Energiesystem unter Verwendung von CO2 und H2 synthetisiert werden können. Polymere Werkstoffe haben in den letzten Jahrzehnten bereits eine wichtige Rolle bei der Weiterentwicklung von Technologien für erneuerbare Energien gespielt, z. B. bei der Energieerzeugung durch Photovoltaikmodule mit Polymerverkapselung, der Energiespeicherung in Batterien mit Polymerseparatoren und der energieeffizienten Wasseraufbereitung mit Polymermembranen. Es wird jedoch immer noch auf "übertechnisierte Materialien" mit geringer Ökoeffizienz zurückgegriffen, wie Fluorpolymere für die Verkapselung von Photovoltaikmodulen oder Membranen, die eine weitere Kostensenkung und Marktdurchdringung behindern. Ziel ist es, einen wesentlichen Beitrag zur Verbreitung von Technologien für erneuerbare Energien und zur Verringerung der Treibhausgasemissionen zu leisten. Um dieses Ziel zu erreichen, hat das Konsortium der Projektpartner ein Forschungsprojekt konzipiert, das aus drei sich ergänzenden thematischen Arbeitspaketen besteht. Durch die gezielte Entwicklung maßgeschneiderter und ökoeffizienter Polyolefin-Materialien werden Innovationen in den Bereichen Photovoltaik, thermische Energiespeicherung und Energieeffizienz in einem hochgradig synergetischen Ansatz vorangetrieben. Zu den Hauptzielen gehören die Entwicklung von verbindenden und funktionellen Polyolefinmaterialien, Hybridlaminaten und Membranen für Doppelglas-PV-Module, die großtechnische Speicherung von Wärmeenergie in Erdwerken und die Ammoniakrückgewinnung aus Abwasser.

Projektträger: FFG

Recovery of valuable biomolecules from microalgae using functionalized membranes

Ziel des Projekts ist die Entwicklung eines innovativen Verfahrens, das auf der Kopplung von enzymatischer Spaltung und Membranfiltration zur effizienten Gewinnung von Lipiden, Polysacchariden und Proteinen aus Mikroalgen basiert, um deren Verwertung zu erleichtern.

Projektträger: DAAD

REPLACER: Recycling von Kunststoffen und Entwicklung hybrider lebender Materialien durch Verwertung von Treibhausgasen zur Herstellung von Produkten mit hoher Wertschöpfung

Klimawandel, Plastikverschmutzung und Ernährungsunsicherheit sind existenzielle Bedrohungen und stellen Europa und die Welt vor enorme Herausforderungen. Die Suche nach nachhaltigen Lösungen ist eine Herausforderung.

Das REPLACER-Projekt geht diese Herausforderungen an, indem es die Vorteile der lebenden und der nicht lebenden Welt kombiniert, um hybride lebende Materialien (HLMs) zu entwickeln und eine nachhaltige Produktion von Proteinen für Futtermittel zu ermöglichen.

Zu den wichtigsten Zielsetzungen des REPLACER-Projekts gehören ein neues Konzept zur Bindung und Nutzung von Kohlenstoff, HLM-basierte Bioreaktor-Prototypen aus recycelten PET-Membranen und mikrobielle Proteine als Grundlage für Tierfutter, die aus Treibhausgasen durch die HLMs produziert werden.

Die Kommerzialisierung des Konzepts wird dazu beitragen, a) Treibhausgase abzuscheiden und die Ziele der EU zur Verringerung der Treibhausgasemissionen zu unterstützen, b) Kunststoffe zu recyceln und den europäischen Green Deal und den Aktionsplan für die Kreislaufwirtschaft zu unterstützen, c) mikrobielle Proteine zu produzieren und die Abhängigkeit der EU von Sojaproteineinfuhren zu verringern.Projektträger: SAB

Hydro4F: Stabilisierte Ultrafiltrationsmembranen mit integrierter Anti-Fouling-Oberfläche - Verbesserung von Stabilität und Performance

Sauberes Wasser, weniger Materialeinsatz, längere Standzeit, neue Märkte – dank individueller Membranveredelung. Ziel dieses Vorhabens ist die Entwicklung einer neuartigen, multifunktionalen Membran-Beschichtung, welche den Bedarf an zusätzlichen und teils toxischen Imprägniermitteln gänzlich obsolet werden lässt. Durch Modifizierung der Membranporen mit einer dünnen Schicht sollen kollabierende Poren verhindert werden. Die zu entwickelnde multifunktionale Stabilisierungsschicht reduziert gleichzeitig die Fouling-Tendenz, bindet vorhandene Feuchte und trocknet folglich nur verzögert aus. Sie verspricht eine erhöhte Membranlebensdauer, bei vermindertem Wartungsaufwand und reduziertem Bedarf an Reinigungschemikalien. Die Einsparung von Energie- und Betriebskosten ganzer Filtrationsanlagen ist besonders für entwickelte Märkte interessant. Darüber hinaus eröffnen sich neue Einsatzfelder u.a. in heißeren Klimaten. Unter Einsatz der Elektronenstrahltechnik können diese Schichten, in einem Schritt und gänzlich ohne zusätzlichen Chemikalieneinsatz, auch im Inneren der Membran an der porösen Oberfläche kovalent gebunden werden. Damit leisten wir einen direkten Beitrag zur Umwelt- und Ressourcen-Schonung.

Projektträger: BMBF

PREMIUM - Intensified process coupling reaction with separation using enzymesfunctionalized membranes for the recovery of bIomolecules from microalgae

Das Ziel des PREMIUM-Projekts ist die Entwicklung eines biokatalytischen Membranreaktors für eine effiziente Gewinnung wertvoller Biomoleküle aus Mikroalgen. PREMIUM beschäftigt sich mit der Prozessintensivierung und stützt sich auf einen multidisziplinären Ansatz: 1) Prozess- und Bioverfahrenstechnik mit der Vorbehandlung der Biomasse, der Entwicklung und Modellierung eines neuen Reaktors, der die enzymatische Reaktion mit der Membranfiltration koppelt; 2) Polymerwissenschaften mit der Entwicklung spezieller Membranen und ihrer Enzymfunktionalisierung durch Elektronenstrahlbehandlung; 3) Materialwissenschaften mit der Entwicklung angepasster Kryo-Elektronenmikroskopie-Methoden, um das notwendige Wissen über die funktionalisierten Membranen (Lokalisierung von Enzymen und Immobilisierungsausbeuten) und ihre Auswirkungen auf das Fouling zu gewinnen, um innovative Prozessentwicklungen und Modellierung zu informieren.

Projektträger: DFG

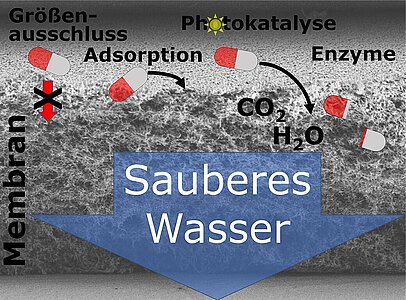

Photokatalytischer Membran-Reaktor zur Entfernung von Spurenschadstoffen aus Wasser

Sauberes Wasser ist ein Menschenrecht, doch durch den Klimawandel kommt es auch in Deutschland zu Trinkwasserknappheit. Trinkwassergewinnung aus Abwasser und Oberflächengewässern könnte eine Lösung sein, aber Spurenschadstoffe wie Medikamentenrückstände, Pestizide und PFAS werden nicht ausreichend entfernt und gelangen in die Umwelt und das Trinkwasser. Der geplante photokatalytische Membran-Reaktor kombiniert Photokatalyse und Membrantechnologie, um diese Schadstoffe abzubauen. Er nutzt Licht und spezielle Katalysatoren, um organische Verunreinigungen zu zersetzen, und die Membran trennt den Katalysator vom gereinigten Wasser. Im Labor zeigte sich das Verfahren vielversprechend, aber großtechnische Daten fehlen. Dieses Validierungsprojekt soll den Reaktor im Pilotmaßstab testen und mit herkömmlichen Methoden wie Ozonierung und Aktivkohle vergleichen. Mit einer Membrantestanlage werden die Technologie unter realitätsnahen Bedingungen geprüft und Energieverbrauch sowie Wirtschaftlichkeit ermittelt. Ziel ist es, die Skalierbarkeit des photokatalytischen Membran-Reaktors zu demonstrieren und seine Anwendbarkeit in der Wasserreinigung zu bewerten, um einen Beitrag zu ökologischer Nachhaltigkeit und Ressourceneffizienz zu leisten.

Projektträger: SAB

Vorlesung

Funktionskontrolle an komplexen Oberflächen

Master Chemie Link

Preise

- 2021: Sächsischer Transferpreis (2. Platz) für das Transferprojekt mit Modellcharakter "Veredelte Membranfilter für die nachhaltige Reinigung von Trink- und Abwasser"

- 2019: Sächsicher Umweltpreis 2019 für das Umweltbildungsprojekt "Sauberes Wasser - eine kostbare Ressource" zusammen mit dem Umweltforschungszentrum und zwei Gymnasien

- 2018: IQ Innovationspreis Mitteldeutschland 2018 (Cluster Chemie/Kunststoffe in Silber für die Innovation "Veredelte Membranfilter für eine preiswerte Wasser- und Abwasserbehandlung")

- 2018: Kurt-Schwabe-Preis 2018 der Sächsischen Akademie der Wissenschaften (für "Selbstreinigende Membranfilter für den umweltfreundlichen Einsatz in der Wasseraufbereitung")

- 2016: Wissenschafts- und Technologiepreis 2016 des IOM (für die "Entwicklung neuer Membranen für die Wasserreinigung")