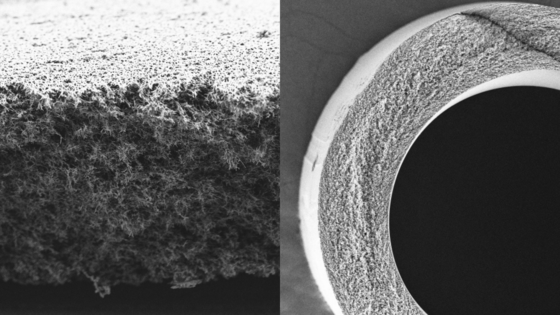

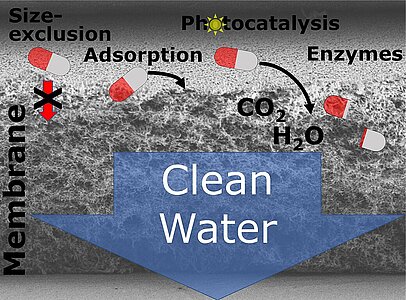

In recent years, membrane-based filtration systems have become increasingly important for numerous applications, e.g. in hemodialysis, water treatment, beverage production, and other industrial filtration processes. The multitude of different applications requires a specific adaptation of the polymer membranes in order to reduce fouling (pore clogging), in order to achieve a stable and high membrane performance, or to generate catalytically active membrane surfaces.

The surface interaction with the medium to be filtered is crucial for the membrane performance. Here we offer a combination of competencies and technologies for the functionalization and characterization of porous polymers with radiation-chemical methods as well as the technological equipment with systems from laboratory to pilot scale.

We focus on applications in the area of water treatment, micropollutant removal, and circular economy.

Team

Scientists

Dr. Agnes Schulze

Dr. Daniel Breite

Dr. Martin Schmidt

Dr. Zahra NiavaraniPhDs

Tom Rüdiger

Tugce Sener Raman

Konrad Leopold

Julia Becker-Jahn

Tim SchreiberTechnical staff

Isabell Thomas

Steffen Weiß

Marco Went

Mathias Kühnert

Amira Abdul Latif

Lutz DrößlerStudents (Master)

Özgü Kirkayak

Highlights

Polymer Membranes for Active Degradation of Complex Fouling Mixtures

Polymer Membranes for Active Degradation of Complex Fouling Mixtures

M. Schmidt, D. Breite, I. Thomas, M. Went, A. Prager, A. Schulze

J. Membr. Sci. 563 (2018) 481-491

https://doi.org/10.1016/j.memsci.2018.06.013Immobilization of different digestive enzymes consisting of proteases, amylases and lipases on polyvinylidene fluoride resulted in biocatalytic active polymer membranes with self-cleaning capability. Activation of enzymes and therefore “switching on” the membrane system was achieved by adjusting pH and temperature leading to an active degradation of fouled substances on its surface. Fouling and self-cleaning experiments with solutions of protein, lipid, carbohydrate, and a mixture were performed and resulted in high recovery of water permeance (99%, 72%, 77%, and 68%, respectively). Furthermore, real samples including river water (75% after first cycle), and household sewage (62%) were examined, as well as first investigations in longtime performance, and stability were performed. Comprehensive membrane characterization was conducted by investigation of the immobilized enzyme concentration, enzyme activity, fouling tests and water permeation monitoring, mercury porosimetry, X-ray photoelectron spectroscopy, scanning electron microscopy, and finally, zeta potential, as well as water contact angle measurements.

Radiation-Induced Graft Immobilization (RIGI): Covalent Binding of Non-Vinyl Compounds on Polymer Membranes

Radiation-Induced Graft Immobilization (RIGI): Covalent Binding of Non-Vinyl Compounds on Polymer Membranes

M. Schmidt, S. Zahn, F. Gehlhaar, A. Prager, J. Griebel, A. Kahnt, et al.

Polymers2021, 13(11), 1849

https://doi.org/10.3390/polym13111849Radiation-induced graft immobilization (RIGI) is a novel method for the covalent binding of substances on polymeric materials without the use of additional chemicals. In contrast to the well-known radiation-induced graft polymerization (RIGP), RIGI can use non-vinyl compounds such as small and large functional molecules, hydrophilic polymers, or even enzymes. In a one-step electron-beam-based process, immobilization can be performed in a clean, fast, and continuous operation mode, as required for industrial applications. This study proposes a reaction mechanism using polyvinylidene fluoride (PVDF) and two small model molecules, glycine and taurine, in aqueous solution. Covalent coupling of single molecules is achieved by radical recombination and alkene addition reactions, with water radiolysis playing a crucial role in the formation of reactive solute species. Hydroxyl radicals contribute mainly to the immobilization, while solvated electrons and hydrogen radicals play a minor role. Release of fluoride is mainly induced by direct ionization of the polymer and supported by water. Hydrophobic chains attached to cations appear to enhance the covalent attachment of solutes to the polymer surface. Computational work is complemented by experimental studies, including X-ray photoelectron spectroscopy (XPS) and fluoride high-performance ion chromatography (HPIC).

High Flux and Adsorption Based Non-functionalized Hexagonal Boron Nitride Lamellar Membrane for Ultrafast Water Purification

High Flux and Adsorption Based Non-functionalized Hexagonal Boron Nitride Lamellar Membrane for Ultrafast Water Purification

R. Das, P. Solís-Fernández, D. Breite, A. Prager, A. Lotnyk, A. Schulze, H. Ago

Chem. Eng. J. 420 (2021) 127721

https://doi.org/10.1016/j.cej.2020.127721Water pollution has prejudicial effects on human health and ecosystems. An advanced membrane technology, which uses less energy for pollutants removal from water, is strongly desired for improving cost efficiency. This study demonstrates a high-flux enabled non-functionalized hexagonal boron nitride (h-BN) lamellar membrane, which retains pollutants through adsorption mediated filtration system–a phenomenon that is not yet studied. The membrane is found to be pH responsive, and acidic solution increases anionic methyl orange (MO) and direct red-80 (DR-80) dyes retention up to ≥90%. It also improves permeance fluxes by ~15 and 61-folds for MO and DR-80, respectively, as compared with the previous studies. Next, the membrane qualifies to be a good adsorbent for pollutants removal. The maximum adsorption capacities of this h-BN membrane for bisphenol A, MO and DR-80 are 125.7, 120.8, and 328.2 mg g−1, respectively. Furthermore, the anti-fouling performance of the membrane has been studied. The membrane exhibits normal fouling tendency, but could be recovered to 80% after washing. The membrane is very stable, and no swelling is observed even in extremely high acidic and basic conditions. The membrane could be regenerated with ethanol treatment and retained dye removal efficiency (around 90%) after four consecutive cycles test.

Photocatalytic degradation of steroid hormone micropollutants by TiO2-coated polyethersulfone membranes in a continuous flow-through process

Photocatalytic degradation of steroid hormone micropollutants by TiO2-coated polyethersulfone membranes in a continuous flow-through process

S. Lotfi, K. Fischer, A. Schulze, A. I. Schäfer

Nat. Nanotechnol. 17 (2022) 417-423

10.1038/s41565-022-01074-8Micropollutants in the aquatic environment pose a high risk to both environmental and human health. The photocatalytic degradation of steroid hormones in a flow-through photocatalytic membrane reactor under UV light (365 nm) at environmentally relevant concentrations (50 ng l–1 to 1 mg l–1) was examined using a polyethersulfone–titanium dioxide (PES–TiO2) membrane. The TiO2 nanoparticles (10–30 nm) were immobilized both on the surface and in the nanopores (220 nm) of the membrane. Water quality and operational parameters were evaluated to elucidate the limiting factors in the degradation of steroid hormones. Flow through the photocatalytic membrane increased contact between the micropollutants and ·OH in the pores. Notably, 80% of both oestradiol and oestrone was removed from a 200 ng l–1 feed (at 25 mW cm–2 and 300 l m–2 h–1). Progesterone and testosterone removal was lower at 44% and 33%, respectively. Increasing the oestradiol concentration to 1 mg l–1 resulted in 20% removal, whereas with a 100 ng l–1 solution, a maximum removal of 94% was achieved at 44 mW cm–2 and 60 l m–2 h–1. The effectiveness of the relatively well-known PES–TiO2 membrane for micropollutant removal has been demonstrated; this effectiveness is due to the nanoscale size of the membrane, which provides a high surface area and facilitates close contact of the radicals with the very small (0.8 nm) micropollutant at an extremely low, environmentally relevant concentration (100 ng l–1).

Synthesis of composite imprinted polymer membranes for the selective removal of 17β-estradiol from water

Z. Niavarani, D. Breite, A. Prager, I. Thomas, M. Kuehnert, B. Abel, R. Gläser, A. Schulze

Mater. Chem. Front. 7 (2023) 4460-4472

10.1039/D3QM00345KComposite microfiltration polyethersulfone membranes incorporating molecularly imprinted particles (MIPs) were developed for efficient and selective adsorption of 17β-estradiol from water. MIP particles were synthesized via precipitation polymerization, with 17β-estradiol as the template molecule. The composite membranes were prepared by embedding the MIPs into the membrane matrices using phase inversion process. Electron beam irradiation was used to covalently immobilize the MIP particles within the membrane scaffold. The synthesized membranes were characterized using scanning electron microscopy (SEM), X-ray photoelectron spectroscopy (XPS), water contact angle analysis, permeation tests and mercury porosimetry. The adsorption loading, selectivity, reusability, and adsorption isotherms were studied through batch and dynamic adsorption experiments. The results indicated significant adsorption loading of 17β-estradiol (12.9 ± 1 mg g−1) and selectivity factors as high as 6.2 and 12.5 for 17β-estradiol in the presence of model micropollutants (such as bisphenol A and citalopram), respectively. Moreover, the composite membranes were regenerated and reused without any significant loss in adsorption loading for 10 subsequent cycles. The maximum adsorption capacity of 17β-estradiol on the composite membrane, calculated by fitting experimental data with the Langmuir equation, was 21.9 mg g−1, which is more than a 200-fold increase in the adsorption loading compared to commercial nanofiltration. These composite microfiltration membranes exhibit a high adsorption loading accompanied by lower pressure requirements for filtration, high water permeation, and extended reusability, rendering them a viable and sustainable option for water purification processes.

Projects

Biomasse 2.0 - Aleno: Anaerobic light-enhanced N-oxidation

Digestion stages of wastewater treatment plants that work according to an upstream principle are characterized by a high biomass retention and a fast conversion rate. These include the reactor types UASB (Upstream Anaerobic Sludge Blanket) and EGSB (Expanded Granular Sludge Bed). However, the current problem is that such systems are not able to carry out denitrification (N-elimination), so that a coupling to activated sludge processes with nitrification and denitrification must still be planned. Denitrification in UASB/EGSB reactors is not possible according to the current state of the art, as the oxygen required for this causes a rapid enlargement of microbial granules. In the planned ALENO project, a new type of upflow reactor is to be developed which combines anaerobic denitrification with high purification efficiency and simultaneous energy generation.

Funded by: VDI/VDE

SolPol-6: Entwicklung maßgeschneiderter und ökoeffizienter Polyolefinwerkstoffe für solare und nachhaltige Energietechnologien

The transition from fossil fuels to renewable energy systems involves shifting from high-temperature to low-temperature processes and moving from complex materials to eco-efficient ones like polymer materials that can be synthesized in a fully solar energy system using CO2 and H2. Polymer materials have already played a significant role in advancing renewable energy technologies in recent decades, such as energy generation through photovoltaic modules with polymer encapsulation, energy storage in batteries with polymer separators, and energy-efficient water treatment with polymer membranes. However, there is still a reliance on "over-engineered materials" with low eco-efficiency, like fluoropolymers for PV encapsulation or membranes, which hinder further cost reduction and market penetration. The aim is to contribute significantly to the dissemination of renewable energy technologies and the reduction of greenhouse gas emissions. To achieve this goal, a research project consisting of three complementary thematic work packages has been designed by the consortium of project partners. Through targeted development of tailored and eco-efficient polyolefin materials, innovations in photovoltaics, thermal energy storage, and energy efficiency will be pursued in a highly synergistic approach. The main objectives include the development of connecting and functional polyolefin materials, hybrid laminates, and membranes for double-glass PV modules, large-scale thermal energy storage in earthworks, and ammonia recovery from wastewater.

Funded by: FFG

Recovery of valuable biomolecules from microalgae using functionalized membranes

The project ambition is to develop an innovative process based on the coupling of enzymatic lysis and membrane filtration for the efficient recovery of lipids, polysaccharides and proteins from microalgae to facilitate their utilization.

Funded by: DAAD

REPLACER: Recycling plastic and developing hybrid living materials by capturing greenhouse gases to produce value-added products

Climate change, plastic pollution and food insecurity are existential threats and pose enormous challenges for Europe and the world. Finding sustainable solutions is a challenge.

The REPLACER project addresses these challenges by combining the advantages of the living and non-living worlds to develop hybrid living materials (HLMs) and enable sustainable production of proteins for feed.

Key objectives of the REPLACER project include a new concept for carbon sequestration and utilization, HLM-based bioreactor prototypes made from recycled PET membranes, and microbial proteins as a basis for animal feed produced from greenhouse gases by the HLMs.

Commercialization of the concept will help (a) capture greenhouse gases and support EU greenhouse gas emission reduction targets, (b) recycle plastics and support the European Green Deal and the Circular Economy Action Plan, (c) produce microbial proteins and reduce EU dependence on soy protein imports.Funded by: SAB

Link for more informations.

Hydro4F: Stabilisierte Ultrafiltrationsmembranen mit integrierter Anti-Fouling-Oberfläche - Verbesserung von Stabilität und Performance

Cleaner water, less material used, longer service life, new markets - thanks to individual membrane finishing. The aim of this project is to develop a new type of multifunctional membrane coating that makes the need for additional and sometimes toxic impregnating agents completely obsolete. By modifying the membrane pores with a thin layer, collapsing pores are to be prevented. The multifunctional stabilizing layer to be developed simultaneously reduces the fouling tendency, binds existing moisture and consequently only dries out with a delay. It promises an increased membrane service life with reduced maintenance requirements and a reduced need for cleaning chemicals. The savings in energy and operating costs for entire filtration systems are particularly interesting for developed markets. In addition, new fields of application are opening up, for example in hotter climates. Using electron beam technology, these layers can be covalently bonded to the porous surface inside the membrane in a single step and without the use of any additional chemicals. In this way, we make a direct contribution to protecting the environment and conserving resources.

Funded by: BMBF

PREMIUM - Intensified process coupling reaction with separation using enzymesfunctionalized membranes for the recovery of bIomolecules from microalgae

The PREMIUM project ambition is the development of a biocatalytic membrane reactor for an efficient recovery of valuable biomolecules from microalgae. PREMIUM deals with the process intensification and relies on a multidisciplinary approach: 1) process and bioprocess engineering, with the biomass pretreatment, the development and modeling of a new reactor coupling enzymatic reaction and membrane filtration; 2) polymer sciences with the development of dedicated membranes and their enzyme functionalization using electron-beam treatment; 3) material sciences with the development of adapted cryo-electron microscopy methods to produce the necessary knowledge on the functionalized membranes (localization of enzymes and immobilization yields) and their impact on fouling, to inform innovative process developments and modeling.

Funded by: DFG

Photokatalytischer Membran-Reaktor zur Entfernung von Spurenschadstoffen aus Wasser

Clean water is a human right, but climate change is also causing drinking water shortages in Germany. Producing drinking water from wastewater and surface water could be a solution, but micropollutants such as drug residues, pesticides and PFAS are not sufficiently removed and end up in the environment and drinking water. The planned photocatalytic membrane reactor combines photocatalysis and membrane technology to break down these pollutants. It uses light and special catalysts to break down organic contaminants, and the membrane separates the catalyst from the purified water. The process has shown promise in the laboratory, but large-scale data is lacking. This validation project aims to test the reactor on a pilot scale and compare it with conventional methods such as ozonation and activated carbon. A membrane test facility will be used to test the technology under realistic conditions and determine energy consumption and cost-effectiveness. The aim is to demonstrate the scalability of the photocatalytic membrane reactor and evaluate its applicability in water purification in order to contribute to ecological sustainability and resource efficiency.

Funded by: SAB

Vorlesung

Function control at comples surfaces

Master Chemie Link

Awards

- 2021: Saxon Transfer Award (2nd price) for the transfer project with model character in the project "Refined membrane filters for sustainable purification of drinking water and wastewater"

- 2019: Saxon Environmental Award 2019 for the environmental education project "Clean water - a precious resource" together with the Centre for Environmental Research and two grammar schools

- 2018: IQ Innovation Award Central Germany 2018 (Cluster Chemistry/Plastics in silver for the innovation “Refined membrane filters for low-cost water and wastewater treatment“)

- 2018: Kurt-Schwabe Award 2018 of the Saxon Academy of Sciences (for “Self-cleaning membranes for an environmentally friendly application in water treatment”)

- 2016: Science and Technology Award 2016 of the IOM (for the “Development of new membranes for water purification applications“)