Imaging techniques are most effective to evaluate the morphology of surfaces in manyfold research and technology issues. Different microscopy techniques are available as digital, optical microscopy (bright / dark field, polarisation, differential interference contrast) and field-emission scanning electron microscopy. Typical applications are given by the analysis of surface structures, defects, and porous matrices ranging from the macroscopic over the microscopic down to the nanoscopic scale.

The analysis of topography and figure are essential in the development of technological fabrication processes, but just as in basic research. Objects of investigation are optical device surfaces (lenses, mirrors) and thin films (metallizations, dielectric coatings, polymer films). For this reason interferometric techniques (stitching, white light), scanning force micropscopy, confocal microscopy as well as optical and tactile profilometry are applied.

Highlights

Improvement of the optical properties after surface error correction of aluminium mirror surfaces

Melanie Ulitschka, Jens Bauer, Frank Frost, Thomas Arnold

J. Eur. Opt. Soc.-Rapid Publ. 17,1 (2021)

https://doi.org/10.1186/s41476-020-00143-6Ion beam finishing techniques of aluminium mirrors have a high potential to meet the increasing demands on applications of high-performance mirror devices for visible and ultraviolet spectral range. Reactively driven ion beam machining using oxygen and nitrogen gases enables the direct figure error correction up to 1 μm machining depth while preserving the initial roughness. However, the periodic turning mark structures, which result from preliminary device shaping by single-point diamond turning, often limit the applicability of mirror surfaces in the short-periodic spectral range. Ion beam planarization with the aid of a sacrificial layer is a promising process route for surface smoothing, resulting in successfully reduction of the turning mark structures. A combination with direct surface smoothing to perform a subsequent improvement of the microroughness is presented with a special focus on roughness evolution, chemical composition, and optical surface properties. As a result, an ion beam based process route is suggested, which allows almost to recover the reflective properties and an increased long-term stability of smoothed aluminium surfaces.

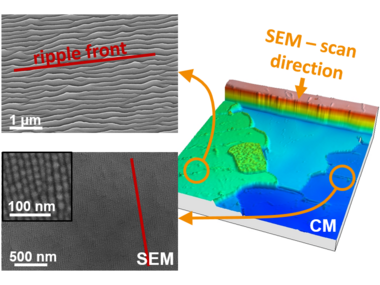

Orientation‐dependent nanostructuring of titanium surfaces by low‐energy ion beam erosion

Jens Bauer, Frank Frost

Surf Interface Anal. 52, 1071– 1076 (2020)

https://doi.org/10.1002/sia.6764Regular nanoscopic ripple and dot patterns are fabricated on poly‐crystalline titanium samples by irradiation with 1.5 keV argon ions at normal incidence. The morphology of the nanostructures is investigated by scanning electron microscopy and scanning force microscopy. The ripple structures exhibit a saw‐tooth cross‐section profile. Electron backscatter diffraction experiments are performed to analyze the local grain structure. The study suggests a distinct correlation of the nanostructure morphology to the crystallographic orientation of the titanium surface.

Finishing of metal optics by ion beam technologies

Jens Bauer, Frank Frost, Antje Lehmann, Melanie Ulitschka, Yaguo Li, Thomas Arnold

Opt. Eng. 58 (9), 092612 (2019)

https://doi.org/10.1117/1.OE.58.9.092612Ultraprecise mirror devices show considerable potential with view to applications in the visible and the ultraviolet spectral ranges. Aluminum alloys gather good mechanical and excellent optical properties and thus they emerge as important mirror construction materials. However, ultraprecision machining and polishing of optical aluminum surfaces are challenging, which originates from the high chemical reactivity and the heterogeneous matrix structure. Recently, several ion beam-based techniques have been developed to qualify aluminum mirrors for short-wavelength applications. We give an overview of the state-of-the-art ion beam-processing techniques for figure error correction and planarization, either by direct aluminum machining or with the aid of polymer or inorganic, amorphous surface films.

Reactive ion beam figuring of optical aluminium surfaces

Jens Bauer, Frank Frost, Thomas Arnold

Reactive ion beam figuring of optical aluminium surfaces

J. Phys. D: Appl. Phys. 50, 085101 (2017)

https://doi.org/10.1088/1361-6463/50/8/085101Ultra-smooth and arbitrarily shaped reflective optics are necessary for further progress in EUV/XUV lithography, x-ray and synchrotron technology. As one of the most important technological mirror optic materials, aluminium behaves in a rather difficult way in ultra-precision machining with such standard techniques as diamond-turning and subsequent ion beam figuring (IBF). In particular, in the latter, a strong surface roughening is obtained. Hence, up to now it has not been possible to attain the surface qualities required for UV or just visible spectral range applications. To overcome the limitations mainly caused by the aluminium alloy structural and compositional conditions, a reactive ion beam machining process using oxygen process gas is evaluated. To clarify the principle differences in the effect of oxygen gas contrary to oxygen ions on aluminium surface machining, we firstly focus on chemical-assisted ion beam etching (CAIBE) and reactive ion beam etching (RIBE) experiments in a phenomenological manner. Then, the optimum process route will be explored within a more quantitative analysis applying the concept of power spectral density (PSD) for a sophisticated treatment of the surface topography. Eventually, the surface composition is examined by means of dynamic secondary ion mass spectrometry (SIMS) suggesting a characteristic model scheme for the chemical modification of the aluminium surface during oxygen ion beam machining. Monte Carlo simulations were applied to achieve a more detailed process conception.