The involvement of students is an integral part of the institute culture at the IOM. The team-oriented atomic sphere of the institute offers ongoing qualification options to students especially in the fields of physics, chemistry, applied mathematics, materials science, and physical and chemical engineering.

Theses (Bachelor/ Master/ Diplom)

In addition to its structured PhD program of the Graduate School, the IOM also assigns topics for final theses of Bachelor and Master programs on an ongoing basis. If you have any questions regarding the supervision of bachelor's or master's theses, please contact the respective heads of the Fields of Research or Cross-section Units directly:

Field of Research: Surfaces of Porous Membrane Filters

Synthesis of molecularly imprinted polymer particles for the removal of endocrine disrupting chemicals from water

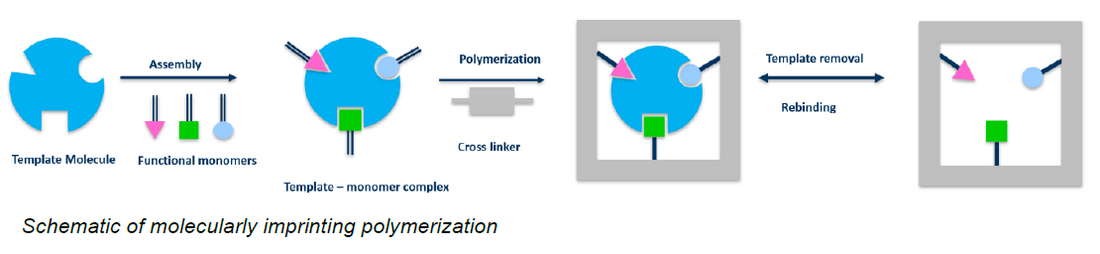

Recently, it has been reported that many chemicals released into the environment disrupt the endocrine system in wildlife and humans. Thus, it is necessary to develop treatment methods to remove endocrine disruptors from water. Molecularly imprinted polymers (MIPs) are promising and facile adsorption materials for separation procedures and chemical analyses. Molecularly imprinting synthesis involves polymerization of functional monomers and a cross-linker around a template. The removal of the template leaves specific binding sites in the polymer with the shape and the orientation of the functional groups complementary to those of the template molecule.

The aim of this project is the synthesis of water compatible MIP particles using ethylene glycol dimethacrylate (EGDMA) as the cross-linker by different polymerization techniques to remove endocrine disrupting chemicals from water.

Methods and techniques:- Synthesis of MIPs by bulk polymerization, precipitation polymerization and emulsion polymerization.

- Characterization: SEM, FT-IR, porosimetry

- Adsorption studies: capacity, selectivity, isotherms, and kinetics

- Regeneration and adsorption-desorption cycle studies

Immobilization of molecularly imprinted particles on membranes

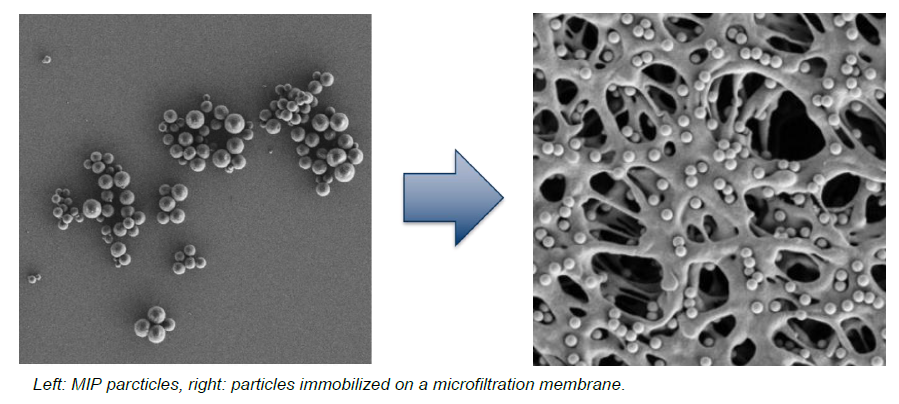

Endocrine disrupting chemicals (EDC), including natural estrogenic hormones have been receiving increased attention related to their occurrence in water sources and their capability to interfere with the human endocrine system. Currently, the literature reports the use of molecularly imprinted polymers (MIPs) as a promising approach for the removal of trace EDCs from water. MIPs are synthetic macroporous materials that have specific recognition cavities with a shape, size, and functional groups complementary to the template molecule. Membrane technology, including microfiltration (MF), in addition, are considered as a viable technology for the removal of EDCs from water. Therefore, MIP particle immobilized membranes would be a useful improvement mode to use in the preparation of novel composite membranes for increasing surface area. This approach makes use of a combinational selection strategy to enhance adsorption capacity.

The aim of this project is the production of microfiltration membranes and the immobilization of MIP particles to enhance the removal of various EDCs from water.

Methods and techniques:

- Membrane preparation by non-solvent-induced phase separation process

- Electron beam-mediated surface engineering

- Immobilization of MIP particles on membranes

- Filtration experiments

- Characterization: SEM, XPS, permeability, porosimetry, contact angle

- Adsorption experiments

Membrane filtration for removal of micro- and nanoplastics from drinking water

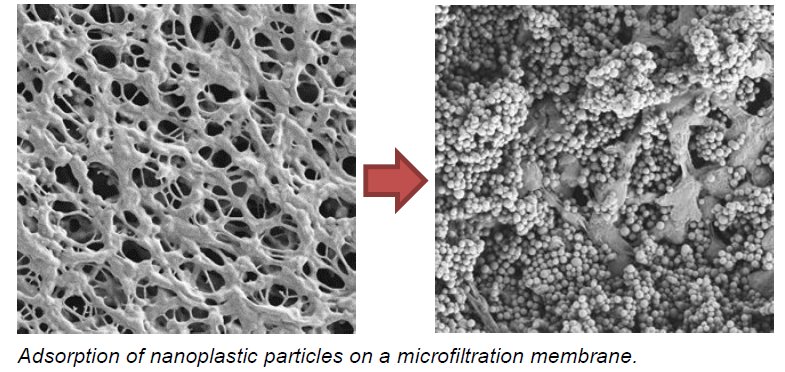

Recent studies have shown that micro- and nano-plastics are absorbed by the human body through food and drinking water, which poses a potential risk to human health.

Depending on the structure of the selected membranes, components of different sizes can be separated (microfiltration: 10-0.1 μm, ultrafiltration: 100-2 nm, nanofiltration: < 2 nm, reverse osmosis: < 0.8 nm), but the pressure required for the filtration (and thus the energy costs) increase with decreasing pore size. Alternative approaches for the removal of micro- and nanoplasticsis are the use of modified microfiltration membranes, that have one of the following functionalities:a) An adsorptive coating. For example, micro- and nanoplastic particles could be adsorptively bonded by electrostatic interactions and thus be separated, while a comparatively low working pressure is required.

b) Immobilized enzymes. These enzymes are able to degrade polyester compounds like PET. The focus of this project will be the evaluation of suitable membrane-solvent-systems, which are able to dissolve the microplastic polymers as well as to allow enzymatic degradation without destruction of the membrane.The aim of these projects is the production of a membrane with appropriate properties for the removal of micro- and nanoplastics from drinking water. For this purpose, first a microfiltration membrane is to be produced, which serves as a carrier layer for the later modification. Subsequently, the coating (adsorber/enzymes) is implemented by electron beam modification. The membranes produced will be comprehensively characterized and the removal of micro- and nanoplastics will be evaluated.

Methods and techniques:- Membrane preparation by non-solvent-induced phase separation process

- Electron beam-mediated surface engineering

- Filtration experiments

- Characterization: SEM, XPS, permeability, porosimetry, contact angle, zetapotential

Laser-structured Membranes

The use of polymeric membrane filters is becoming increasingly important in modern, efficient filtration technologies. Especially in the areas of water treatment, sterile filtration, blood purification and beverage production, these materials play a decisive role with specifically adjustable pore sizes. Furthermore, chemical surface interactions and surface morphology need to be considered to avoid fouling of substances within the filtration process.

The aim of this project is the investigation of morphology changes as well as changes of the chemical nature of membrane surfaces after laser structuring. The understanding of this treatment shall enable the directed surface engineering of a membrane surface to generate super-hydrophilic surfaces, low fouling and high permeability performances.

Methods and techniques:- Laser-structuring of a polymer membrane (in collaboration with the group of Dr. Zimmer at the IOM)

- Characterization: SEM, AFM, XPS, permeability, porosimetry, contact angle, zetapotential

- Performance: fouling tests, flow direction in cross-flow cell depending on lasered channel directions

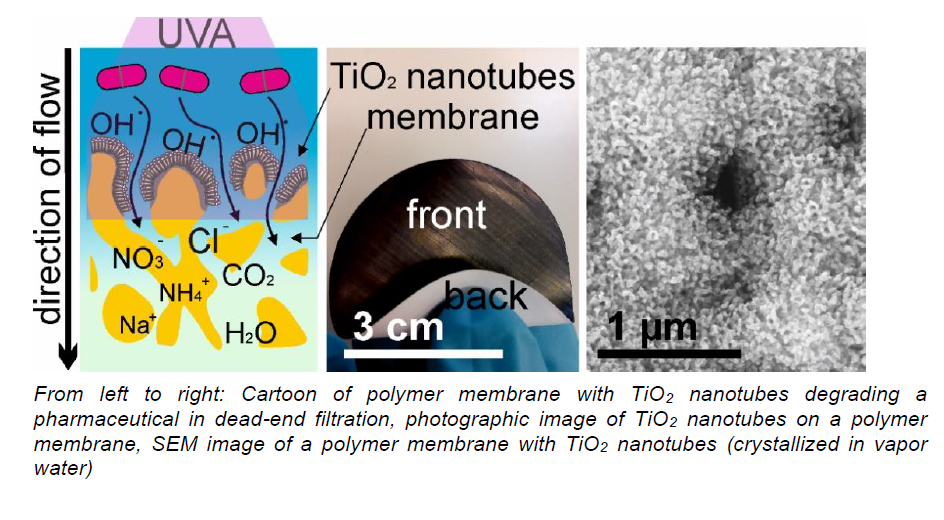

Laser-induced crystallization of TiO2 nanotubes on polymer membranes for water treatment

Titanium dioxide (TiO2) has been used for more than 100 years mainly as a white pigment for a wide variety of products. The semiconducting properties in combination with other important qualities such as corrosion resistance, chemical stability and non-toxicity allow the use of TiO2 as a solar cell or photocatalyst for the decomposition of organic pollutants. The group has developed an electrochemical method that can be used to synthesize TiO2 nanotubes on a polymer membrane surface. The formed TiO2 nanotubes are amorphous, thus non-photocatalytic active. TiO2 forms three different crystalline morphologies, namely anatase, rutile and brookite. So far TiO2 nanotubes have been crystallized with water at low temperatures, but the tubes deform to some extent and only the crystalline form of anatase is obtained. A new method to crystallize TiO2 nanotubes with laser annealing arose in the last years. Next to anatase also rutile can be formed and the nanotubular structure can be preserved.

Crystalline TiO2 nanotubes allow a rapid photocatalytic degradation of drugs (e.g., diclofenac and ibuprofen) in a continuous process.The aim of this project is the investigation of the crystallization and morphology change with laser annealing of TiO2 nanotubes on a polymer membrane.

Methods and techniques:- Laser annealing of TiO2 nanotubes on a polymer membrane (in collaboration with the group of Dr. Zimmer at the IOM)

- Characterization: SEM, XPS, Raman, XRD, investigation of photocatalytic activity (degradation of pollutants) under UV light irradiation

Nanopatterning of Polymers with (Reactive) Ion Beam Etching (RIBE)

Ion Beam techniques are widely used in the production of optical devices. In the process the substrate is coated with a resist layer, which is typically a polymer (e.g. phenolic resin). The resulting structure of the substrate depends on the structure of the resist layer. It is possible to planarize the substrate or to create a regularly structure (e.g. optical grids).

The parameters influencing the structure of the substrate are well-known, but it is possible that defects from the resist layer are transferred into the substrate, which lowers the quality of the optical device. With a better understanding how to influence the structure of the polymer it could be possible to inhibit the formation of defects in the resist layer. Also the modification of polymer membranes and the tuning of their properties could be possible.

The aim of this project is to investigate the influence of an ion bombardment on the structure and chemical properties of polymer membranes.

Methods and techniques:- Nanopatterning of a polymer membrane (in collaboration with the group of Dr. Frost at the IOM)

- Characterization: SEM, AFM, XPS, permeability, porosimetry, contact angle, zetapotential

- Performance: fouling tests, flow direction in cross-flow cell(Functionalization of polymer membranes)

Visible light photocatalytic active membranes for pollutant removal in water

Classical photocatalysts used to remove pollutants are titanium dioxide (TiO2) or zinc oxide (ZnO). But TiO2 and ZnO are non-active in the visible light region due to their large band gap. Since 2004 it is known that bismuth tungstate (Bi2WO6) is able to mineralize organic molecules under visible light irradiation (> 440 nm, bandgap of 2.75 eV).

In this project Bi2WO6 shall be immobilized on a polymer microfiltration membrane for degradation of organic pollutants like pharmaceuticals, pesticides or hormones under visible light irradiation. The polymer membrane acts as a support for Bi2WO6, is easy to handle, comparable low in costs, has a high throughput and large surface area. The group has a large expertise in applying TiO2 in different forms and crystalline morphologies on a membrane and testing the degradation of different pollutants. The photocatalyst Bi2WO6 is a promising candidate to be immobilized on a polymer membrane next to TiO2, but has the advantage to be active under visible light irradiation.

The aim of this work is to synthesize Bi2WO6 nanoparticles, immobilize them on a microfiltration membrane and analyze their photocatalytic activity under visible light irradiation.

Methods and techniques:- Synthesis of Bi2WO6 nanoparticles by solvothermal synthesis

- Immobilization on a polymer microfiltration membrane

- Characterization: SEM, XPS, investigation of photocatalytic activity (degradation of pollutants) under UV and visible light irradiation

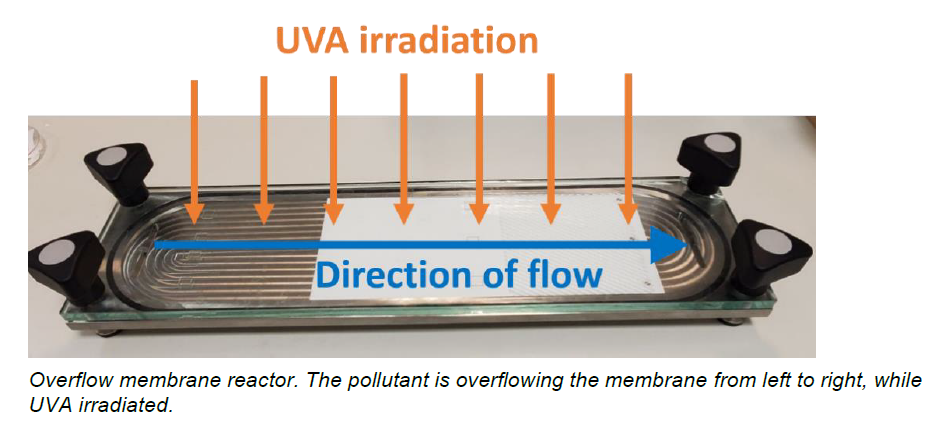

Overflow membrane reactor for removal of pollutants from water via adsorption and photocatalysis

Membranes cannot only be used as a filter but also as an adsorbent and support for a photocatalyst like TiO2. Different flat sheet membrane reactor types like dead-end and cross-flow filtration are usually applied. But for adsorption and photocatalysis an overflow membrane reactor might be more effective as the contact and reaction time of organic molecules with the membrane surface and photocatalyst is increased. The group has a large expertise in modifying polymer membranes with photocatalysts like TiO2 and their use in a batch and dead-end reactor for pollutant (pharmaceutical) removal. Next to photocatalysis, the proposed reactor shall be applied for a combination of photolysis of diclofenac and adsorption of phototransformation products to a PVDF membrane.

The aim of this project is the application of an overflow membrane reactor for photocatalysis and adsorption in combination with photolytic transformation of diclofenac and investigation of reactor parameters like flow, membrane size, pollutant concentration and operation with different spacers.

Methods and techniques:- Setup of overflow membrane reactor, change of parameters

- Characterization: Removal of pollutants (concentration change, UV-Vis spectroscopy and HPLC) at different parameters

Field of Research: Ultra-precision Surfaces

Laser writing processes for roll-to-roll replication technologies

- 3D micro structuring of glass by femtosecond laser machining for direct writing of optics

- Smoothing of laser-written optical surfaces by post processing

- Development of pattern transfer processes by laser ablation

- Self-organization processes in laser irradiation of surfaces and thin films

- Laser processing and surface functionalization for wettability control

- 3D microobjects by laser structuring and self-folding processes

Contact:

Dr. K. Zimmer

Group Leader Laser based micro- and nanostructuring

klaus.zimmer(at)iom-leipzig.de

+49 (0)341 235-3287