The goal of the activities of the cross-section unit “tool development” is to provide optimized, in part unique ion beam, electron, laser and plasma tools that are commercially not available, for the different aspects of surface engineering done at the Institute like smoothing, free-forming, structuring and activating as well as coating of surfaces. The tools are developed in close collaboration with the fields of research, in general, using modelling and simulation as a guide. An effective development of these tools requires a solid understanding of the involved physical processes. For this purpose, the tools are studied experimentally using dedicated (in situ) plasma and beam diagnostics that are in part developed in-house as well. In addition, in fundamental research studies, e.g. charge-exchange processes and the creation / emission of secondary particles are addressed.

Die Gruppe des Hertz-Elektronenstrahllabors stellt Elektronenstrahlquellen bis 10 MeV für die Materialmodifikation zur Verfügung und entwickelt entsprechende Bestrahlungskonzepte unter Berücksichtigung von Tiefendosisverteilungen. In Kooperation mit den Forschungsbereichen und externen Partnern werden zudem spezielle analytische Techniken wie Pulsradiolyse, Laserphotolyse und PEEM für Grundlagenuntersuchungen zur Wechselwirkung von Elektronen und Photonen mit Materie eingesetzt.

Highlights

Development and test of a cost-efficient gridded ion thruster propulsion system for small satellites – IonJet

F. Scholze, F. Pietag, H. Adirim, M. Kreil, M. Kron, R. Woyciechowski, C. Bundesmann, D. Spemann

J. Electric Propulsion 1 (2022) 28

DOI: 10.1007/s44205-022-00028-5Within the DLR-funded joint project IonJet of IOM and Aerospace Innovation GmbH, an engineering model of a low-cost electric propulsion system for small satellites was developed. Whereas the flow control subsystem is based on the MICROJET 2000 system launched 2016 on the BIROS satellite, the thruster subsystem is based on a novel patent-pending gridded ion thruster where the neutralizer is integrated in the ion thruster allowing for simultaneous ion and electron extraction. This design allows reducing the number of components and consequently costs and system complexity. The entire system was successfully tested under vacuum conditions regarding ignition and stable operation of the propulsion system. In the performance tests, thrusts of 1 mN could be achieved using Xenon gas as propellant at a total power consumption of less than 50 W as well as specific impulses larger than 1000 s, including the gas consumption of the neutralizer. In addition, first tests with Krypton gas were performed showing that for the same total power the achievable thrust is reduced to 55% – 68% of that for Xenon.

Two-Photon Laser-Induced Fluorescence in a Radiofrequency Ion Thruster Plume in Krypton

C. Eichhorn, F. Scholze, C. Bundesmann, D. Spemann, H. Neumann, H. Leiter

Journal of Propulsion and Power 35 (2019) 1175

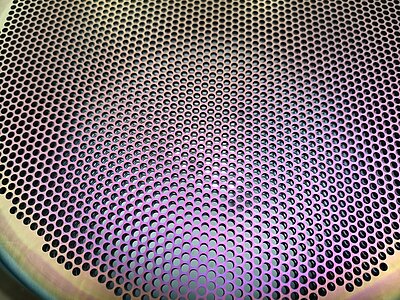

DOI: 10.2514/1.B37487Gridded ion engines apply an electrically biased extraction grid system in order to accelerate ionized particles, which, in this way, form the „propellant“ of the device. An intact grid geometry, in particular the preservation of the grid hole diameters, is a basic requirement with regard to the long-life cycle of such thrusters used in spaceflight applications. The knowledge of spatially resolved densities of plasma species near the thruster exit plane is important for a quantitative estimation of plasma- and surface processes that may lead to undesirable grid hole widening (grid hole erosion). This work demonstrates how neutral particle densities of a relevant propellant (krypton) can be experimentally measured during thruster operation using non-intrusive techniques based on laser spectroscopy.

Nanoscale ion implantation using focussed highly charged ions

P. Räcke, R. Wunderlich, J.W. Gerlach, J. Meijer, D. Spemann

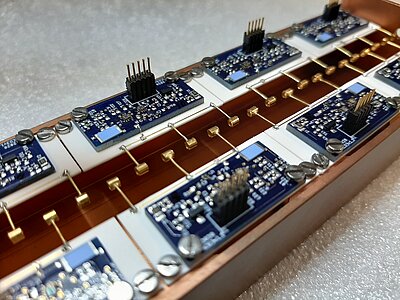

New Journal of Physics 22 (2020) 083028

DOI: 10.1088/1367-2630/aba0e6Ion implantation is not only an established technique for semiconductor industry and research, but also a key method enabling ground-breaking research in novel quantum technologies like quantum sensing and computing, e.g. based on donors in silicon or the nitrogen-vacancy-(NV)-centre in diamond. For the realisation of quantum computing, a main challenge is the scalability of the qubit fabrication. For ion implantation, this means combining a high throughput with spatially precise placement of a counted number of single dopants or defects is crucial. For this purpose, a focussed ion beam (FIB) based ion implanter equipped with an electron beam ion source (EBIS) able to produce highly charged ions was set up. The ion optical system was optimised and beam spot sizes below 200 nm achieved, showing that nanoscale ion implantation using an EBIS is feasible. As an example of its utilisation, we demonstrate the direct writing of nitrogen-vacancy centres in diamond using mask-less irradiation with focussed Ar8+ ions with sub-micron three-dimensional placement accuracy.

The Systematics of Ion Beam Sputtering for Deposition of Thin Films with Tailored Properties

C. Bundesmann, H. Neumann

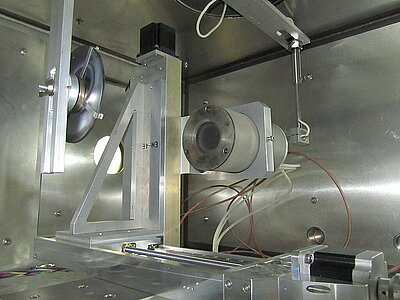

J. Appl. Phys. 124 (2018) 231102

DOI: 10.1063/1.5054046Thin films are very important elements in daily-life devices but also in high-end technologies. There are numerous techniques for deposition of thin films. One option is ion beam sputter deposition (IBSD). This technique utilizes a low-energy ion beam for bombardment of a target made of the thin film material. Upon ion-target interaction, target material gets sputtered and condenses on the object of interest. IBSD belongs to the group of physical vapor deposition (PVD) techniques. In comparison to other PVD techniques, it has some advantages: improved adhesion, dense film structure, less defects, higher purity, and better controlled composition. At the IOM, a unique vacuum chamber was set up, which allows the comprehensive investigation of the fundamental systematics of IBSD. Doing so, for the first time, the full potential of IBSD has been revealed.

Dynamic determination of secondary electron emission using a calorimetric probe in a plasma immersion ion implantation experiment

F. Haase, D. Manova, D. Hirsch, S. Mändl, H. Kersten

Plasma Sources Sci. Technol. 27 (2018) 044003

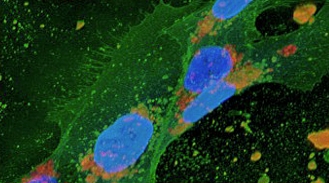

LinkThe emission of secondary electrons is a characteristic feature of all surfaces under ion bombardment. While strong variations with the actual surface chemistry are known, direct dynamic measurements during surface bombardment are very difficult. Using a calorimetric probe, it is possible to obtain values for the secondary electron emission yield for metallic and isolating surfaces, e.g. polymers, as well a temporal evolution during plasma or ion treatment. The removal of oxide layers or the formation of compound layers are prominent examples here.