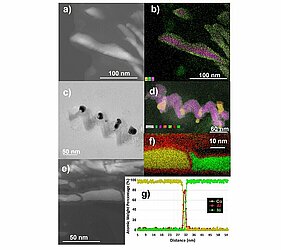

This proposal is dedicated to the exploration of methods for the advanced manufacturing of spatially coherent, homogeneous, and high-quality compound one-dimensional nano-heterostructures by principles of oblique angle deposition in combination with assist ion bombardment (iGLAD). One assist ion source implemented into the fabrication process will be subsequentially operated for i) substrate pre-patterning via ion erosion, ii) control of phase and stoichiometry via reactive ion bombardment, and iii) nanostructure size control via ion figuring. A hypothesis-driven approach is employed to investigate nucleation, growth, interface formation, surface patterning and nanostructure crafting for the fabrication of metal oxide nano-heterostructures in correlation to process parameters such as ion energy, ion current density, angle of incidence and ion mass, using ZrO2-MoO3-x as a model substance. In-situ spectroscopic ellipsometry at arbitrary sample positions will be applied to monitor material development during manufacturing in real-time. The new understanding of growth processes will be supported by a comprehensive analysis of particle fluxes which are integral to ion assisted fabrication, and by Monte-Carlo based simulations of the particle transport during deposition. If successful, a modified Thornton diagram of microstructure evolution in 1D nanostructures as a function of ion bombardment and oblique particle fluxes will be established.

This proposal is based on mutual scientific interest in low-energy reactive ion beam processing for advanced additive manufacturing and combines expertise from Dr. Eva Schubert, Associate Professor at the University of Nebraska-Lincoln (U.S.A.) and Dr. Frank Frost, Head of Division for Ion Beam Assisted Patterning and Smoothing at the Leibniz Institute of Surface Engineering (IOM) in Leipzig (Germany). High resolution STEM imaging in combination with EDX elemental analysis will be conducted by Dr. René Feder, Team Manager Hybrid Systems, from IOM sub-contractor Fraunhofer-Institute for Microstructures of Materials and Systems in Halle/Saale (Germany).