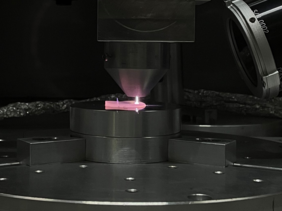

Atmospheric pressure plasma jet processes were developed at the IOM more than 20 years ago and have been used in ultra-precision machining ever since. The further development of the process and tools has opened up new fields of application. For example, only inert gas is used in plasma jet polishing. The thermally induced redistribution of material in the absence of reactive gases leads to a reduction in surface roughness, particularly in the high-frequency spatial wavelength range, and can therefore potentially replace mechanical-abrasive polishing.

The current investigations in this field were published in the recent publication “Freeform surfaces manufactured with a combination of ultra-fine grinding and plasma jet polishing”. In collaboration with the project partner EAH Jena, a new process chain for the production of optical freeforms was developed, which combines a three-stage grinding process optimized by the EAH Jena with a final plasma jet polishing. The application of the thermally induced polishing process by the researchers at the IOM enables a significant reduction in the surface roughness of ground freeform surfaces. The preservation of the original geometry and the short process time make this technology an important tool for the cost-efficient production of free-form surfaces, such as those used in optics and photonics.

Publication:

Freeform surfaces manufactured with a combination of ultra-fine grinding and plasma jet polishing

H. Müller, S. Henkel, C. Schulze, S. Frank, J. Bliedtner, T. Arnold

J. Eur. Opt. Society-Rapid Publ. 2025, 21, 12

https://doi.org/10.1051/jeos/2025007

This work was supported by financial support by German Federal Ministry of Education and Research (BMBF) within the framework of the VIP+ program (No. 03VP08631) “Validation of a new process chain for the production of freeform optics by Plasma Jet smoothing of ultra-finished freeform surfaces”.