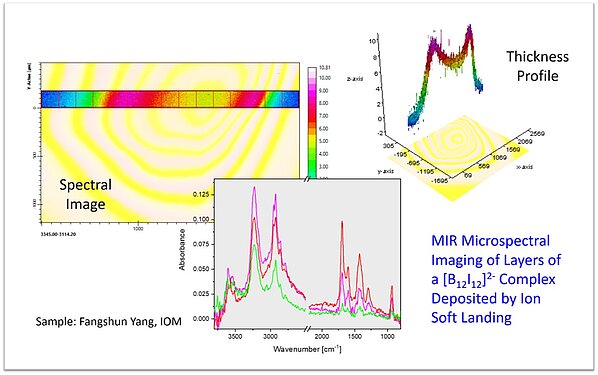

Spectral imaging methods constitute an independent key research topic of the analytics group. Depending on the specific experimental approach, such state-of-the-art methods enable the monitoring of the spatial distribution of chemical and physical parameters across the surface of samples on length scales from micrometers to macroscopic scales. Microspectroscopic imaging techniques are based on mid-infrared (MIR) or Raman microscopy. In combination with a focal plane array (FPA) detector MIR microscopy allows space-resolved measurements up to the optical resolution limit. Investigations with this method at IOM are focused e.g. on microfluidics or nitrogen centers in electron-beam irradiated diamonds. On the other hand, the use of a NIR camera or a multiplexed NIR spectrometer allows the continuous spectroscopic analysis of large-area or web-type materials up to a width of several meters. Applications of such techniques are mainly settled in industrial process control.

Highlights

Near-infrared hyperspectral imaging for monitoring the thickness distribution of thin poly(3,4-ethylenedioxythiophene):poly(styrene sulfonate) (PEDOT:PSS) layers

O. Daikos, M. Naumann, K. Ohndorf, C. Bundesmann, U. Helmstedt, T. Scherzer

Talanta 223 (2021) 121696

10.1016/j.talanta.2020.121696The thickness of thin layers of the conductive polymer PEDOT:PSS in the range between about 60 and 300 nm was determined by a near-infrared spectroscopic method using a hyperspectral camera. The reflection spectra of the layers do not contain bands, but consist of a moderate slope of the overall reflectance in the range between 1320 and 1850 nm. Despite the low thickness, the spectra show an extremely strong dependence on the thickness of the layers, which allows their use for quantitative measurements. The prediction of quantitative thickness data from the reflection spectra was based on a chemometric approach using the partial least squares (PLS) algorithm. Calibration was carried out by means of spin-coated layers of PEDOT:PSS, whose thickness was determined by white-light interferometry and stylus profilometry. Finally, this resulted in a calibration model with a root mean square error of prediction (RMSEP) of about 9 nm. After external validation of this model, it was used for quantitative imaging of the thickness distribution in PEDOT:PSS layers. The precision of the predicted values was confirmed by comparison with data from the reference methods. Moreover, it was shown that this approach can be also used for hyperspectral imaging of the thickness of thin printed layers and structures of this conductive polymer on polymer film or paper with excellent thickness resolution. This analytical approach opens new possibilities for in-line process control by large-scale monitoring of thickness and homogeneity of thin layers of conductive polymers.

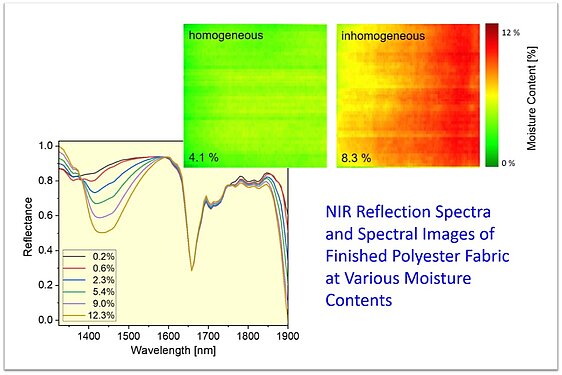

Monitoring of the residual moisture content in finished textiles during converting by NIR hyperspectral imaging

O. Daikos, T. Scherzer

Talanta 221 (2021) 121567

10.1016/j.talanta.2020.121567Hyperspectral imaging was used for large-scale monitoring of the residual moisture in wide textile webs at the end of the drying process that follows their washing or finishing by impregnation in aqueous solutions or dispersions. Such data are essential for optimizing the energy efficiency and the precise control of the drying process. Quantitative analysis of the recorded spectral data was carried out with multivariate regression methods such as the partial least squares (PLS) algorithm. Reference data for calibration of the prediction models were determined by gravimetry. The drying of textile materials from both natural or synthetic fibers possessing different water absorption capacities (cotton, polyamide, polyester), which were partially finished with an optical brightener, was investigated. Moisture contents in the range from 0 to about 12 wt% were considered in the calibration models. For all systems, the root mean square error of prediction (RMSEP) for the residual moisture was found to be about 0.5 wt%, that is, about 1 g/m². In addition to the quantitative determination of the water content, hyperspectral imaging provides detailed information about its spatial distribution across the textile web, which may help to improve the control of the drying process. In particular, it was demonstrated that the developed methods were capable of detecting and visualizing inhomogeneous moisture distributions. Averaging of the individual values of the moisture content predicted from all spectra across the surface of the textile samples resulted in a very close correlation with the corresponding gravimetric reference values. Due to the averaging process, the difference between both values is generally lower than RMSEP even in case of samples with inhomogeneous distribution of the moisture. The high precision and the broad capabilities of the developed analytic methods for in-line monitoring of the moisture content hold the potential for an efficient process control in technical textile converting processes.

Development of a PLS approach for the determination of the conversion in UV-cured white-pigmented coatings by NIR chemical imaging and its transfer to other substrates

O. Daikos, K. Heymann, T. Scherzer

Prog. Org. Coat. 132 (2019) 116

10.1016/j.porgcoat.2019.03.008Near-infrared (NIR) chemical imaging was used for in-line monitoring of the conversion in thick UV-cured white-pigmented acrylate coatings applied to various substrates such as glass, stainless steel, PVC and glass fiber reinforced plastic (GRP) boards. Quantitative results were obtained by means of chemometric calibration models based on the partial least square (PLS) algorithm. Two spectroscopic techniques were tested for their potential for the characterization of the conversion after UV irradiation with a broad range of UV doses in order to provide reliably precise reference data for the calibration. NIR reflection spectroscopy using band integration of the acrylate band at 1620 nm was selected as method of choice. Using glass as substrate for the coatings at the beginning, a PLS model was established and evaluated for its performance to predict the conversion in independent samples. The acrylate conversion was predicted with an error of 2 %. Generally, any calibration model is specific to a well-defined sample system (e.g. material and thickness of substrate and coating). In order to reduce the effort required for the development of specific calibration models for each substrate used in this study, methods for calibration transfer were developed. It was found that the requirements for such transfer depend on the optical properties of the substrate. In case of stainless steel and PVC boards, simple preprocessing of the spectra by baseline correction and normalization (similar to samples on glass) led to satisfactory results, which is confirmed by prediction of the conversion with similar error margins as for coatings on glass. In case of glass fiber boards, the spectrum of the pristine GRP board had to be subtracted from the spectrum of the coated sample before the transfer of the PLS model. The resulting prediction error (RMSEP) was found to be 3.6 %. The comparison between this transferred and a specific PLSGRP model that was built up for evaluation only proved the high performance of the transferred PLS model. These results clearly demonstrate the high efficiency of the transfer of specific PLS models to different (but similar) sample systems such as coatings applied to other substrates. In addition to the quantitative determination of the conversion, the developed calibration models were also used for the evaluation of its spatial distribution across the surface of UV-cured coatings.

Near-infrared chemical imaging used for in-line analysis of functional finishes on textiles

G. Mirschel, O. Daikos, T. Scherzer, C. Steckert

Talanta 188 (2018) 91

10.1016/j.talanta.2018.05.050This paper demonstrates for the first time that near-infrared (NIR) chemical imaging can be used for in-line analysis of textile finishing processes based on impregnation. In particular, it was shown that this analytical method is sufficiently sensitive for the quantitative determination of the application weight of rather thin layers of finishing chemicals. Quantitative analysis of the data recorded by a hyperspectral camera (1320-1900 nm) was based on chemometric approaches using the partial least squares (PLS) algorithm. In this work, a flame retardant and a polyvinyl acetate-based stiffening agent applied to polyester or cotton fabrics, respectively, were studied with application weights in the range between about 1 and 50 g m-2. For both systems, the prediction error (RMSEP) was found to be about 1.5 to 2 g m-2. Averaging of the predicted individual values of the application weight of the finishes across the complete surface of the fabric resulted in a very close correlation with the corresponding reference values obtained by gravimetry. Furthermore, NIR chemical imaging was used for the detection of remaining traces of a size (a processing agent) after washing, which had to be washed-out before subsequent processing steps. Results of the present investigations prove that even for very thin size layers between 0.4 and 5.5 g m-2 the application weight can be predicted with a precision of about 0.4 g m-2.

Apart from the quantitative determination of the application weights, the use of NIR chemical imaging for the analysis of finished textiles was mainly directed towards the investigation of the spatial distribution or the homogeneity of the applied colorless finishes across the surface of the fabrics. It was shown that this method is able to detect and visualize various inhomogeneities on the finished textiles resulting for instance from processing defects or from various technical effects that may influence the drying process and consequently the spatial distribution of the finish. Moreover, the distribution of traces of size that had been sprayed purposely on a washed polyester fabric could be detected.

All measurements in the present study were carried under conditions that were very similar to those in typical technical processes (e.g. with respect to line speed). Therefore, the outstanding performance of the method opens an immense potential for application in process and quality control.

Near-Infrared Chemical Imaging Used for In-line Analysis of Inside Adhesive Layers in Textile Laminates

Gabriele Mirschel, Olesya Daikos, Tom Scherzer, Carsten Steckert

Anal. Chim. Acta 932 (2016) 69-79

https://doi.org/10.1016/j.aca.2016.05.015This paper demonstrates for the first time that near-infrared (NIR) chemical imaging can be used for in-line analysis of textile lamination processes. In particular, it was applied for the quantitative determination of the applied coating weight and for monitoring of the spatial distribution of hot melt adhesive layers using chemometric approaches for spectra evaluation. Layers with coating weights between about 25 and 130 g m-2 were used for the lamination of polyester fabrics and nonwovens as well as for polyurethane foam. It was shown that quantitative data with adequate precision can be actually obtained for layers applied to materials with significantly heterogeneous surface structure such as foam or for hidden layers inside fabric laminates. Even the coating weight and the homogeneity of adhesive layers in composites consisting of black textiles only could be quantitatively analyzed. The prediction errors (RMSEP) determined in an external validation of each calibration model were found to range from about 2 g m-2 to 6 g m-2 depending on the specific system under investigation. All calibration models were applied for chemical imaging in order to prove their performance for monitoring the thickness and the homogeneity of adhesive layers in the various textile systems. Moreover, they were used for the detection of irregularities and coating defects. Investigations were carried out with a large hyperspectral camera mounted above a conveyor. Therefore, this method allows large-area monitoring of the properties of laminar materials. Consequently, it is potentially suited for process and quality control during the lamination of fabrics, foams and other materials in field-scale.