Using ion-beam assisted deposition (IBAD) or ion-beam assisted molecular beam epitaxy (IBA-MBE), a hybrid of conventional thin film and ion-beam techniques, thin films with modified or optimized properties, e.g. with a high mass density, can be synthesized. This technique is distinctive in that during deposition in vacuum the thin film is simultaneously subjected to irradiation with an energetic ion beam. By this, an additional energy and momentum input into the surface of the growing film is present, which can influence surface diffusion processes in order to optimize crystallinity and microstructure of the resulting thin film. Advantages of this technique are the high controllability of the deposition process due to the well-separated material fluxes, the wide parameter range, as well as the possibility to deposit amorphous, polycrystalline and nearly single crystalline thin films. The main application area of this technique at the IOM is the synthesis of nitride thin films.

Expertise

- Deposition of thin films

- In situ and ex situ characterization of surfaces and thin films

- Ion-beam assisted deposition (IBAD) of polycrystalline thin films

- Energy and mass selected ion-beam assisted deposition (EMS-IBAD)

- Ion-beam assisted molecular beam epitaxy (IBA-MBE)

Highlights

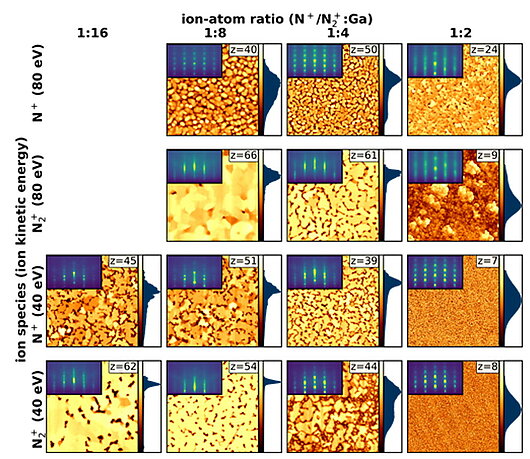

Influence of nitrogen ion species on mass-selected low energy ion-assisted growth of epitaxial GaN thin films

M. Mensing, P. Schumacher, J.W. Gerlach, S. Herath, A. Lotnyk, B. Rauschenbach

Applied Surface Science 498 (2019) 143830

https://doi.org/10.1016/j.apsusc.2019.143830The application of an ion energy and ion mass selected ion beam assisted deposition setup to investigate the influence of hyperthermal atomic and molecular nitrogen ion species during the initial stages of epitaxial GaN thin film growth is reported here. A precise selection of the ion beam parameters enables the preferred growth of either the metastable zinc blende GaN phase or the stable wurtzite GaN phase on 6H-SiC(0001) substrates. Using N2+ assisting ions thin films of high crystalline quality could be deposited even at ion kinetic energies of 80 eV.

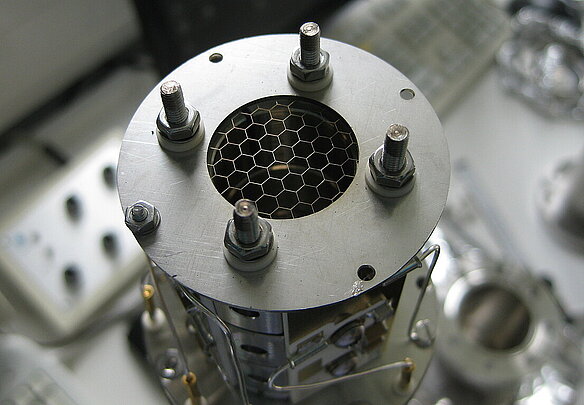

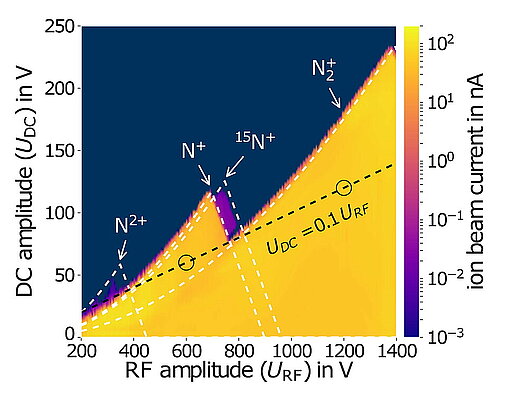

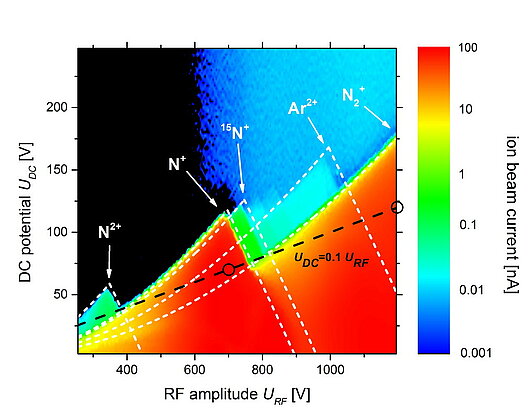

Ion mass and energy selective hyperthermal ion-beam assisted deposition setup

J.W. Gerlach, P. Schumacher, M. Mensing, S. Rauschenbach, I. Cermak, B. Rauschenbach

Review of Scientific Instruments 88 (2017) 063306

https://doi.org/10.1063/1.4985547A compact setup for ion mass and ion energy selective ion-beam assisted deposition (IBAD) is presented. For this purpose, a combination of a nitrogen ion source and a customized quadrupole mass filter system was realized, equipped with entry and exit ion optics, ion beam deflection, as well as integrated ion-beam current monitoring. The quadrupole setup provides control over the composition of the ion beam consisting either of atomic or molecular nitrogen ions. Moreover, for both ion species the kinetic energy can be controlled within the region of hyperthermal energies.

Ion beam assisted deposition of thin epitaxial GaN films

B. Rauschenbach, A. Lotnyk, L. Neumann, D. Poppitz, J.W. Gerlach

Materials 10 (2017) 690

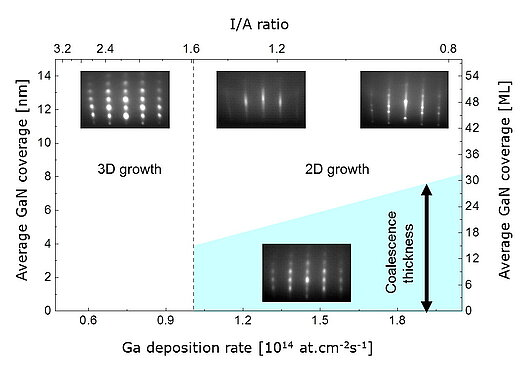

https://doi.org/10.3390/ma10070690Nitrogen ion beam assisted molecular beam epitaxy (ion energy < 25 eV) is used here to deposit GaN thin films on 6H-SiC(0001) substrates at 700 °C. It is demonstrated that the film growth mode can be controlled by varying the ion to atom ratio, where 2D films are characterized by a smooth topography, a high crystalline quality, low biaxial stress, and low defect density. Typical structural defects in the films were identified as basal plane stacking faults, low-angle grain boundaries forming between polytype and twin boundaries.