We “engineer” plasmas with the goal to optimize them for surface engineering, including plasma-assisted deposition of thin films and coatings. Our research covers

- fundamental plasma and plasma-surface interaction studies needed to design plasma sources,

- diagnose these plasmas with state-of-the-art techniques, followed by

- integration of these sources in deposition / etching / functionalization systems to obtain surfaces and thin film systems optimized for a specific application.

This implies an interdisciplinary approach: we cover the range from basic plasma physics, mechanical and electrical engineering, surface-related chemistry and modeling to application-relevant scaling. While our research traditionally is associated plasmas and processes of cathodic arcs and magnetron sputtering in its various incarnations, including high power impulse magnetron sputtering (also known as “HiPIMS”), we increasingly also consider alternative plasmas including those at atmospheric pressure.

Expertise

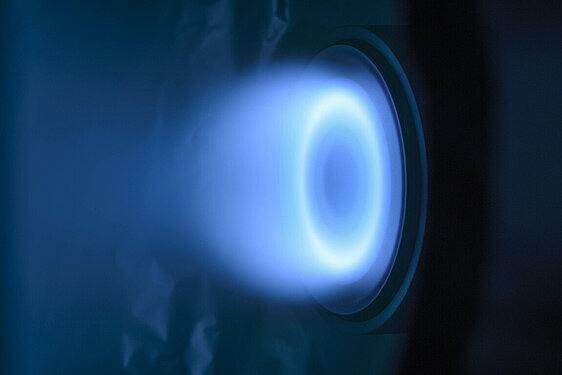

- Thin film deposition by magnetron discharges (Magnetron Sputtering, High Power Impulse Magnetron Sputtering (HiPIMS), Reactive Sputtering)

- Filtered Cathodic Arc Deposition

- Plasma diagnostics (Optical Imaging, Optical Emission Spectroscopy, Mass/Charge Spectrometry)

- Inorganic thin film and surface characterization (in close cooperation with other experts at the institute)

- Plasma Modelling (in cooperation with internal and external experts)

Highlights

Toward decoupling the effects of kinetic and potential ion energies: Ion flux dependent structural properties of thin (V, Al) N films deposited by pulsed filtered cathodic arc

Y. Unutulmazsoy, D. Kalanov, K. Oh, S. Karimi Aghda, J.W. Gerlach, N. Braun, F. Munnik, A. Lotnyk, J.M. Schneider, A. Anders

Journal of Vacuum Science & Technology A 41 (2023) 6

https://doi.org/10.1116/6.0002927Original abstract: Pulsed filtered cathodic arc deposition involves formation of energetic multiply charged metal ions, which help to form dense, adherent, and macroparticle-free thin films. Ions possess not only significant kinetic energy, but also potential energy primarily due to their charge, which for cathodic arc plasmas is usually greater than one. While the effects of kinetic ion energy on the growing film are well investigated, the effects of the ions’ potential energy are less known. In the present work, we make a step toward decoupling the contributions of kinetic and potential energies of ions on thin film formation. The potential energy is changed by enhancing the ion charge states via using an external magnetic field at the plasma source. The kinetic energy is adjusted by biasing the arc source (“plasma bias”), which allows us to approximately compensate the differences in kinetic energy, while the substrate and ion energy detector remain at ground. However, application of an external magnetic field also leads to an enhancement of the ion flux and hence the desired complete decoupling of the potential and kinetic energy effects will require further steps. Charge-state-resolved energy distribution functions of ions are measured at the substrate position for different arc source configurations, and thin films are deposited using exactly those configurations. Detailed characterization of the deposited thin films is performed to reveal the correlations of changes in structure with kinetic and potential energies of multiply charged ions. It is observed that the cathode composition (Al:V ratio) strongly affects the formation of the thermodynamically stable wurtzite or the metastable cubic phase. The external magnetic field applied at the arc source is found to greatly alter the plasma and, therefore, to be the primary, easily accessible “tuning knob” to enhance film crystallinity. The effect of “atomic scale heating” provided by the ions’ kinetic and potential energies on the film crystallinity is investigated, and the possibility to deposit crystalline (V,Al)N films without substrate heating is demonstrated. This study shows an approach toward distinguishing the contributions stemming from kinetic and potential energies of ions on the film growth, however, further research is needed to assess and distinguish the additional effect of ion flux intensity (current).

Decoupling the effects of potential energy, kinetic energy, and ion flux on crystallinity of V-Al and V-Al-N thin films in pulsed filtered cathodic arc deposition

D. Kalanov, S. Mandazhiev, J. Franze, A. Anders, Y. Unutulmazsoy

Surface and Coatings Technology 497 (2025) 131720

https://doi.org/10.1016/j.surfcoat.2024.131720Original abstract: Deposition using filtered pulsed cathodic arc plasma is known to produce dense and adherent thin films due to energetic ions which carry significant ion kinetic and potential energies. The role of potential energy coming from multiply charged metal ions in film formation remains under-explored, since the enhancement of charge states in cathodic arcs is coupled with an increased flux and kinetic energies of ions. In this work, the influence of ion potential energy on structural properties of thin films is investigated, while keeping the mean ion kinetic energies unchanged. Two material systems are considered: metallic V-Al and compound V-Al-N in non-reactive and reactive deposition, respectively. For V-Al plasma and thin films, the impact of metal ion potential energy is demonstrated. In the V-Al-N case, in addition to metal ions, activated (namely, ionized, dissociated, and excited) nitrogen species are found to be a significant factor for crystalline growth of the metastable cubic phase.

Postannealing-induced intermetallic phase formation in NiPt thin films deposited via direct current and high-power impulse magnetron sputtering

A. Kühne, W. Diyatmika, Y. Unutulmazsoy, M. Rudolph, A. Finzel, J. W. Gerlach, A. Lotnyk, B. Abel, A. Anders

Journal of Vacuum Science & Technology A 43 (2025) 023408

https://doi.org/10.1116/6.0004249Original abstract: Intermetallic phases are preferred to reduce the amount of platinum used for catalytic applications as compared to solid solution alloys, due to their stability at elevated temperatures while preserving or even enhancing the catalytic properties. Here, we show a two-step process to form an intermetallic NiPt L10 phase. In this work, NiPt solid solution thin films were fabricated by direct current and high-power impulse magnetron sputtering processes, which allow for precise thickness and chemical composition control. Following deposition, an additional annealing step is used to form the desired intermetallic phase. We show that the required annealing time for intermetallic phase formation is considerably reduced for NiPt thin films with a thickness of 240 nm, as compared to its bulk counterpart.

Heteroepitaxial growth of Ga2O3 thin films on Al2O3 (0001) by ion beam sputter deposition

D. Kalanov, J.W. Gerlach, C. Bundesmann, J. Bauer, A. Lotnyk, H. von Wenckstern, A. Anders, Y. Unutulmazsoy

Journal of Applied Physics 136 (2024) 015302

https://doi.org/10.1063/5.0211179Original abstract: Deposition of epitaxial oxide semiconductor films using physical vapor deposition methods requires a detailed understanding of the role of energetic particles to control and optimize the film properties. In the present study, Ga2O3 thin films are heteroepitaxially grown on Al2O3 (0001) substrates using oxygen ion beam sputter deposition. The influence of the following relevant process parameters on the properties of the thin films is investigated: substrate temperature, oxygen background pressure, energy of primary ions, ion beam current, and sputtering geometry. The kinetic energy distributions of ions in the film-forming flux are measured using an energy-selective mass spectrometer, and the resulting films are characterized regarding crystalline structure, microstructure, surface roughness, mass density, and growth rate. The energetic impact of film-forming particles on the thin film structure is analyzed, and a noticeable decrease in crystalline quality is observed above the average energy of film-forming Ga+ ions around 40 eV for the films grown at a substrate temperature of 725 ˚C.

High-resolution observation of cathodic arc spots in a magnetically steered arc plasma source in low pressure argon, nitrogen, and oxygen atmospheres

K. Oh, D. Kalanov, P. Birtel, A. Anders

J. Appl. Phys. 130 (2021) 183304

https://doi.org/10.1063/5.0072021Original abstract: Cathode spots in a magnetically steered arc source were studied under low-pressure noble gas (Ar) and reactive gas (N2, O2) atmospheres. The plasma was observed using a streak camera coupled with a long-distance microscope to study the evolution of cathode spots with high temporal and spatial resolution. We find two well-known types of cathode spots: “type 1” for less bright spots eroding the compound layer on the cathode surface and bright “type 2” spots on (clean) metallic surfaces. Cathode spots are characterized by a sequence of micro explosions that give the impression of a moving spot, which, in the presence of a magnetic field, is generally in the retrograde direction. However, the apparent displacement can also go in the opposite, the Amperian direction, especially when nitrogen is present. In oxygen, spot ignition often happens in approximately the same location repeatedly. For type 2 spots, we detected an apparent motion mainly in the retrograde direction with distinct jumps to new locations. Via the effects of spot appearance, we note the competing effects of cathode cleaning by spot-induced material removal (erosion) and compound formation in the presence of reactive gas. The streak images were analyzed by fast Fourier transformation, and we found that the arc fluctuations are stochastic without specific frequencies. The colored random noise (CRN) index tends to be reduced in the presence of a compound layer, indicating an enhanced spot ignition probability. A reduced CRN index implies reduced feedback (influence) of previously active spots, which is most apparent in the presence of elevated oxygen pressure.