Complex shaped surfaces for applications in precision optics and microelectronics require manufacturing accuracies down to a few nanometers. Such requirements apply to the long wavelength shape as well as the medium wavelength structural region and microroughness. Particle beam-based tools such as ion beams and plasma jets are used to achieve this accuracy. The diversity of technologically relevant materials such as technical glasses, advanced ceramics and metals makes it necessary to first investigate and characterize the specific atomic interaction mechanisms between tool and surface. With an understanding of the processes taking place, these are then used specifically to develop deterministic, i.e., process simulation-based, processing technologies for ultra-precise shaping and shape correction of optical surfaces. For example, aspheres and free-form surfaces can be produced that meet the highest demands in terms of shape and roughness.

Expertise

- Ion Beam Figuring of glasses, crystals, ceramics and metals

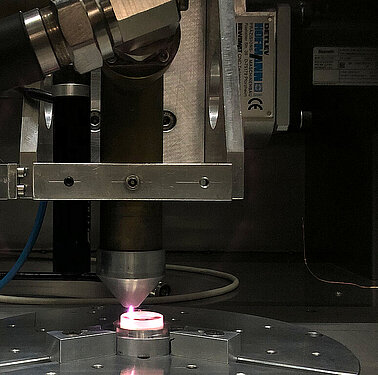

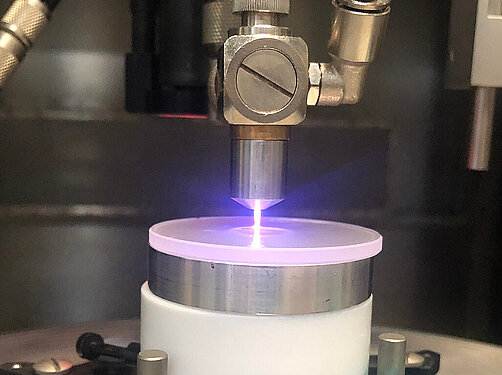

- Plasma Jet Machining of optical glasses, Si, SiC

- Freeform generation and correction

Highlights

An investigation on effectiveness of temperature treatment for fluorine-based reactive plasma jet machining of N-BK7®

F. Kazemi, G. Böhm, T. Arnold

Plasma Process Polym. 17 (2020)

https://doi.org/10.1002/ppap.202000016In this study, a fluorine‐based reactive plasma jet is investigated as a promising tool for ultraprecise surface machining of N‐BK7®. Plasma‐generated particles react with an N‐BK7 surface to create volatile and nonvolatile compounds. The desorption of volatile compounds results in an etched surface, whereas nonvolatile compounds form a residual layer in the etched area, causing unpredictable effects on the etching rate. Surface temperature treatment is proposed to improve the machining procedure with respect to deterministic material removal, leading to predictable results. It is shown that, at an elevated surface temperature, the residual layer properties are modified in favor of improved etching performance. The etching behavior of N‐BK7 is compared with fused silica to verify the optimality of the obtained results.

Advances in precision freeform manufacturing by plasma jet machining

T. Arnold, G. Böhm, F. Kazemi

EPJ Web Conf. 238 (2020) 03001

https://doi.org/10.1051/epjconf/202023803001Atmospheric pressure plasma jet machining technology provides a flexible and efficient way to fabricate precise freeform optics. Due to the pure chemical material removal mechanism based on a dry etching process using fluorine containing gas, the choice of materials that can be treated is limited. Fused silica, Si, SiC or ULE® are easy to machine since the etching products formed are solely volatile. Recently, plasma jet machining has been also adopted to treat optical glasses like N-BK7® which contain amongst others alkali metals that form a solid residual layer during etching. In the paper a new approach to apply deterministic plasma jet etching on optical glass coping with complex etch characteristics caused by the residual layer is introduced.

Residual layer removal of technical glass resulting from reactive atmospheric plasma jet etching by pulsed laser irradiation

F. Kazemi, T. Arnold, P. Lorenz, M. Ehrhardt, K. Zimmer

Plasma Chem. Plasma Process 40 (2020) 1241-1251

https://doi.org/10.1007/s11090-020-10101-2A procedure consisting of reactive atmospheric plasma jet (RAPJ) etching and laser ablation is proposed for the machining of N-BK7. Etching of metal oxide containing glass like N-BK7 by a fluorine-based plasma jet exhibits currently limitations due to the formation of non-volatile reaction products that remain on the glass surface as a layer. The capability of laser-based removal of residual layers is compared to water-based solving of the residual layer. After RAPJ etching of N-BK7 the samples are cleaned either by a water-based solvent or by the ablation with a nanosecond pulsed ultraviolet laser. The laser irradiation results in a localized removal of the residual layer. It is demonstrated that the roughness of the laser-cleaned N-BK7 surface is similarly low as solvent-based cleaned samples. However, the pulsed laser enhanced cleaning allows a dry processing at atmospheric pressure as well as a localized processing with a high lateral resolution.

Improved ion beam tools for ultraprecision figure correction of curved aluminum mirror surfaces

J. Bauer, M. Ulitschka, F. Pietag, T. Arnold

J. Astron. Telesc. Instrum. Syst. 4 (2018) 046003

https://doi.org/10.1117/1.JATIS.4.4.046003Aluminum mirrors offer great potential for satisfying the increasing demand in high-performance optical components for visible and ultraviolet applications. Ion beam figuring is an established finishing technology and in particular a promising technique for direct aluminum figure error correction. For the machining of strongly curved or arbitrarily shaped surfaces as well as the correction of low-to-mid spatial frequency figure errors, the usage of a high-performance ion beam source with low tool width is mandatory. For that reason, two different concepts of ion beam generation with high ion current density and narrow beam width are discussed. A concave ion beam extraction grid system is used for apertureless constriction of ion beams in the low millimeter range. An oxygen ion beam with a full-width at half-maximum (FWHM) of 4.0 mm with an ion current density of 29.8 mA∕cm2 was achieved. For even smaller ion beams, a conic aperture design with a submillimeter-sized exit opening was tested. A nitrogen ion beam with an FWHM down to 0.62 mm with an ion current density of 4.6 mA∕cm2 was obtained. In situ ion current density mapping is performed by scanning Faraday probe measurements. Special interest is set on the data evaluation for submillimeter ion beam analysis.

New Freeform Manufacturing Chains based on atmospheric Plasma Jet Machining

T. Arnold, G. Böhm, H. Paetzelt

J. Eur. Opt. Soc.-Rapid 11 (2016) 16002

DOI: 10.2971/jeos.2016.16002New manufacturing chains for precise fabrication of asphere and freeform optical surfaces including atmospheric Plasma Jet Machining (PJM) technology will be presented. PJM is based on deterministic plasma-assisted material removal. It has the potential for flexible and cost-efficient shape generation and correction of small and medium-sized optical freeform elements. The paper discusses the interactions between the plasma tools and optical fused silica samples in the context of the pre-machined and intermediate surface states and identifies several plasma jet machining methods for freeform generation, surface correction, and finishing as well as suitable auxiliary polishing methods. The successful application of either processing chain is demonstrated.