Apart from the conventional diffraction and reflectivity methods available up to now at the IOM the new substitute x-ray diffraction/reflectivity system now offers additional new techniques for the non-destructive analysis and characterization of crystalline and amorphous materials.

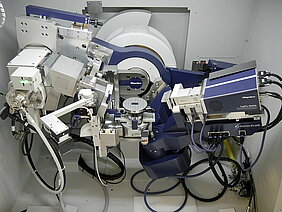

By means of a modern high-power rotating anode x-ray source, several beam-shaping x-ray optics elements as well as a highly sensitive area detector of the newest generation, on the one hand different samples can now be measured by using a highly intense x-ray beam, while the beam shape can be optimized for the respective required measurement task. On the other hand, x-rays diffracted or scattered by a sample can still be detected and evaluated even when they are of low intensity. Furthermore, the highly precise 5-axis-goniometer installed in the system together with various available degrees of freedom in movement of the x-ray source, of the sample attachments as well as of the detector offers a variety of measurement scenarios.

The new instrumentation adds modern diffraction and scattering methods to the x-ray analytics lab as well as to the portfolio of the cross-section unit ‘Material Characterization and Analytical Service’. This provides new research possibilities and at the same time the scientific quality of the work at the institute is secured for the future.

This substitutional x-ray diffractometer/reflectometer system of type SmartLab by Rigaku company was funded with 614 000 Euro by the Free State of Saxony in order to keep the infrastructure of the IOM modern. Installation of the system started in October 2021. Upon acceptance regarding radiation safety by the responsible administration office, regular measurement activities with the x-ray diffractometer/reflectometer system will begin in February 2022.